100 Percent Inline Inspection in Automotive Production with 3D Laser Profile Sensors

Measurement Tasks Along the Automotive Process Chain from Body Shop to Final Assembly

In the automotive industry, precision, speed and process reliability determine efficiency and quality. Components such as body parts, battery modules, weld seams or tires must be inspected inline under real production conditions and without slowing down the cycle time. This is exactly where AT Sensors comes in.

Robust 3D laser profile sensors are the backbone of systems for 100 percent inline inspection directly within the production process, independent of ambient light, material surfaces or vibrations. Typical applications in the automotive industry include geometry inspection of body components, weld seam inspection, battery and cell inspection, as well as profile and runout inspection of tires.

Thanks to high profile rates, precise height resolution and intelligent on sensor chip processing, even highly dynamic processes can be monitored reliably. The result is reproducible measurement results, less scrap and measurably higher process stability, even in 24/7 operation.

3D Image Processing

-

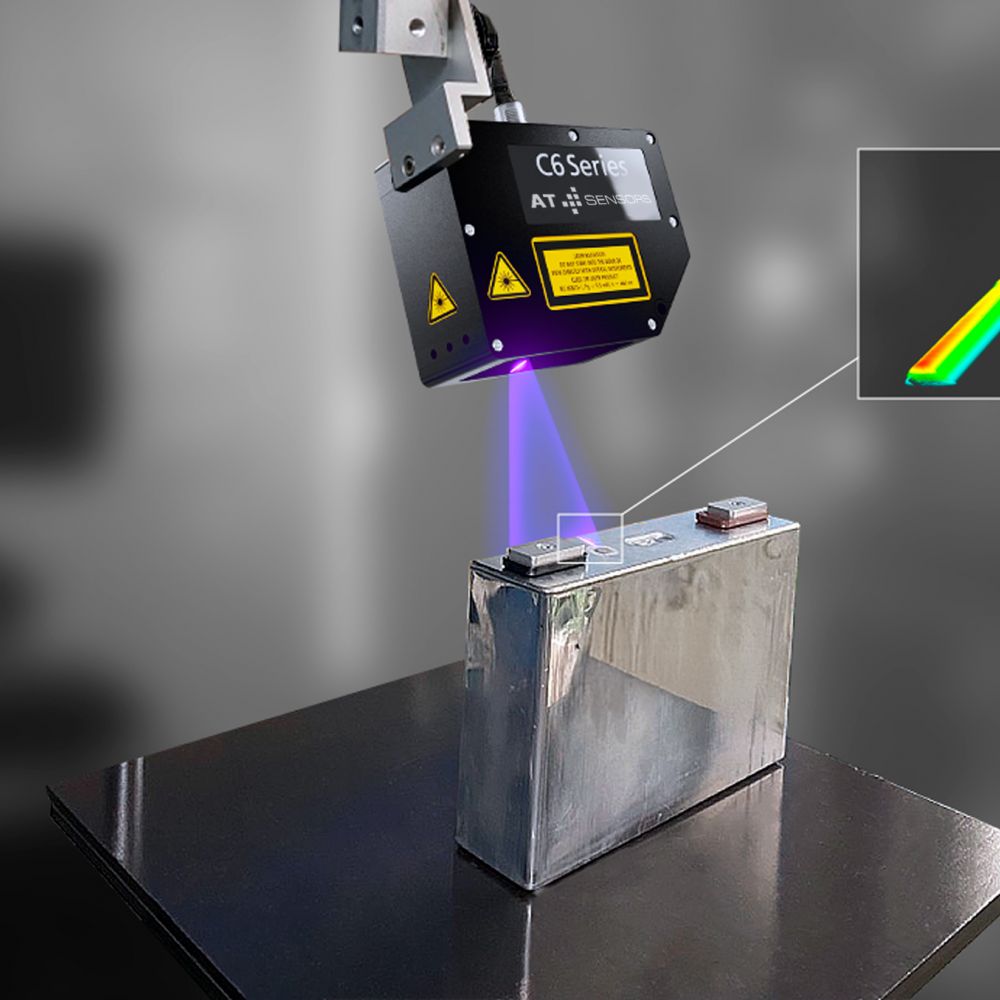

Battery Inspection

In the automotive industry, precision is of the utmost importance, especially when it comes to the inspection of EV batteries. The CS 1280 is a crucial step towards error-free production and ensures the highest quality through its outstanding specifications. If you are looking for the best instrument for battery inspection, you should consider the CS 1280. -

Pin Inspection

The revolutionary connector application from aku.automation and AT Sensors, which inspects over 1.7 million pins every day with unprecedented precision, is setting a new benchmark in the electronics industry. At the heart of this revolutionary solution is AT Sensors’ XCS 3D sensor, a true game changer that is transforming the inspection of electronic connectors for all automotive manufacturers. This collaboration between aku.automation and AT therefore offers a pioneering technology that not only ensures maximum reliability in quality assurance, but also redefines the standards for the entire industry. -

Brake Disc Inspection

The combination of speed and precision makes the CS 4090 3D sensor an indispensable tool in modern automotive production. Manufacturers can now ensure that their brake discs meet the strictest quality and safety requirements, and all of this in a fraction of the time previously required. Investing in the C6-4090CS is not only an investment in safety but also in efficiency. -

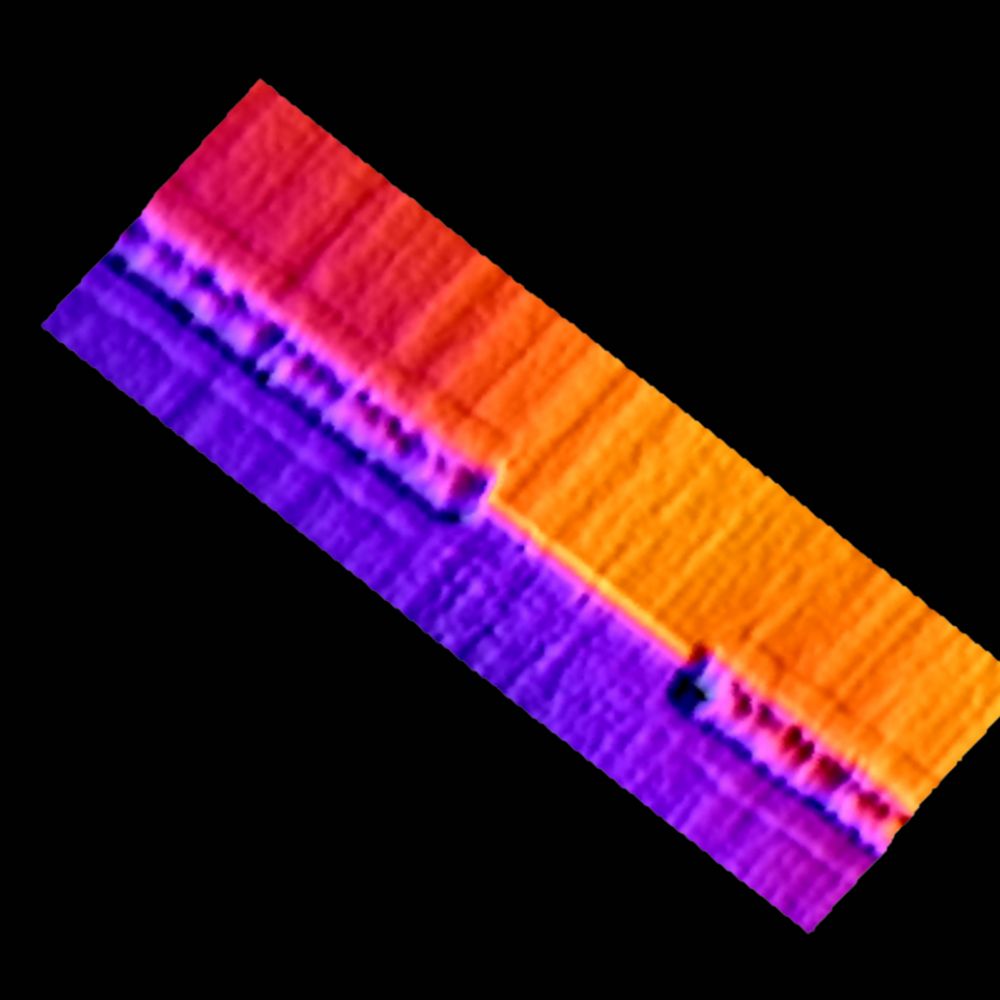

Weld Seam Inspection

The CS 1280 3D sensor sets a new standard in weld seam inspection in the automotive industry. Its speed and adaptability enable manufacturers to raise their quality standards while operating more efficiently. In an industry where safety and quality are paramount, the CS 1280 provides real added value.

IR Thermal Imaging Processing

-

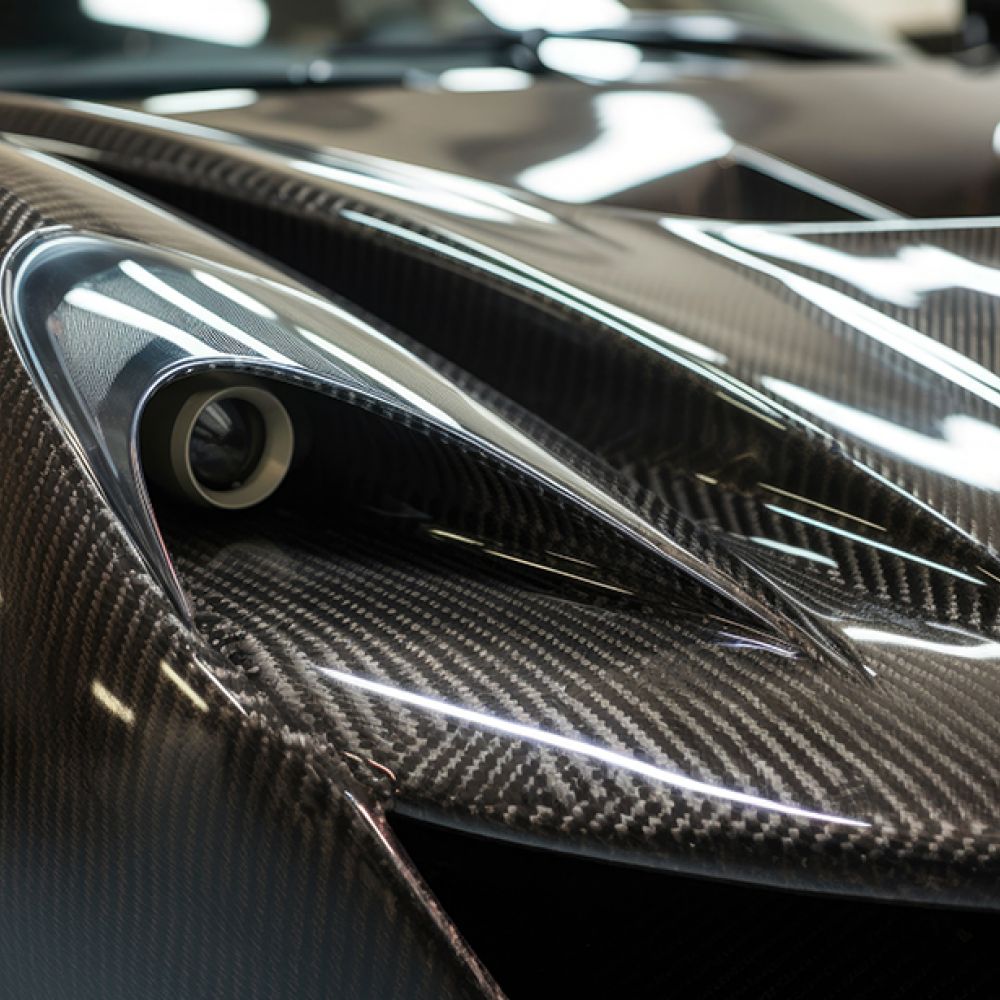

Carbon Fiber Inspection

The IRSX infrared camera represents the latest technology in quality assurance for carbon fibers. With its precise detection and fast response time, it plays a crucial role in ensuring the high quality and performance of carbon fibers while further optimizing production processes. -

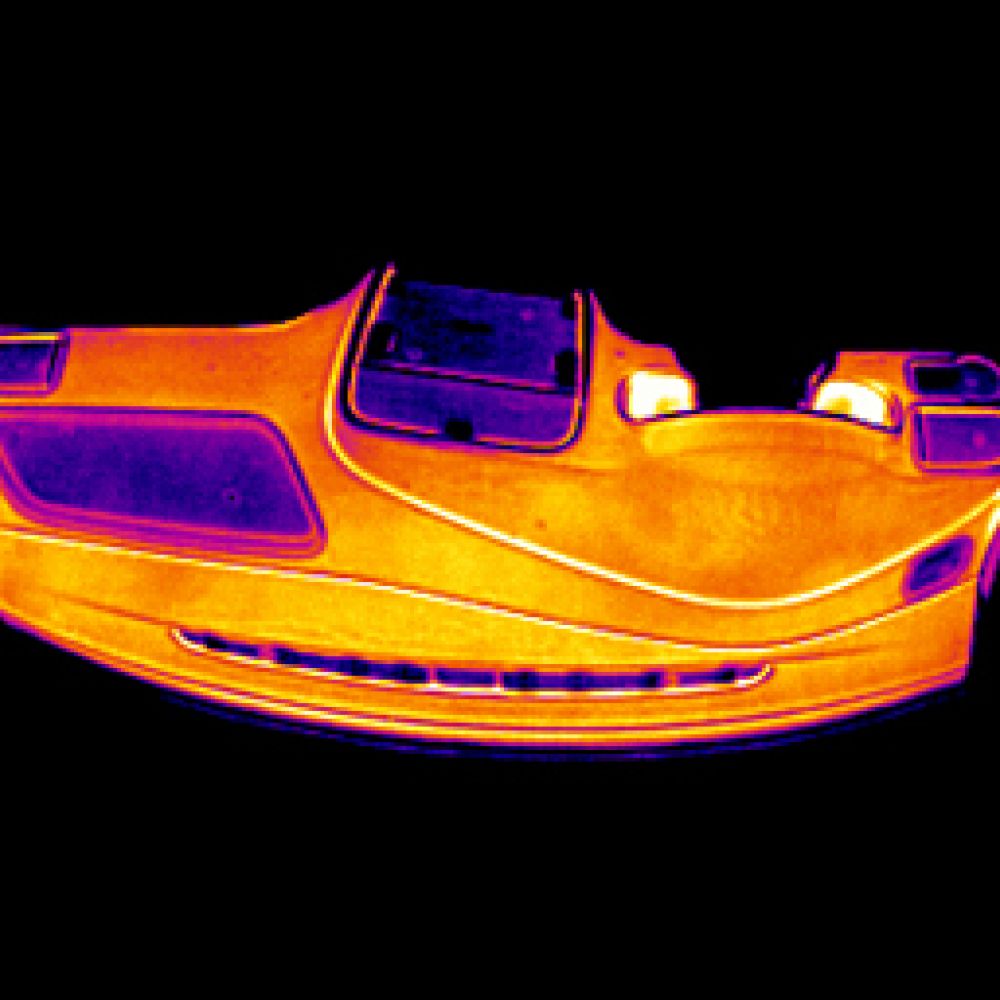

Dashboard Check

Monitoring and inspecting dashboards are crucial tasks in the automotive industry. With the IRSX infrared camera, car manufacturer can ensure that their dashboards meet the highest quality and safety standards. With its sensitivity and easy integration, the IRSX is an essential tool for modern vehicle production. -

Thermoforming

In an industry where precision and quality need to be maintained, the IRSX infrared camera offers a groundbreaking solution for monitoring the thermoforming process. Its contribution to reducing production costs and improving product quality makes it an indispensable tool in the modern plastics industry.