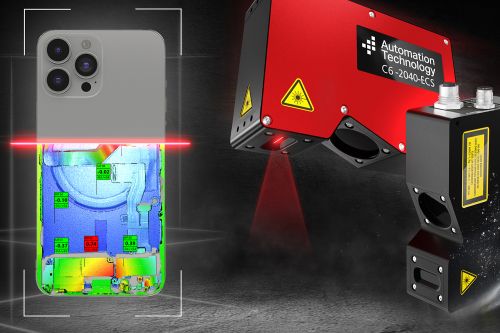

The fastest 3D sensors in the world

We offer the fastest 3D sensors worldwide in terms of resolution and speed. The advantages include a specially developed sensor chip and WARP technology resulting in the world’s fastest 3D profiling.

-

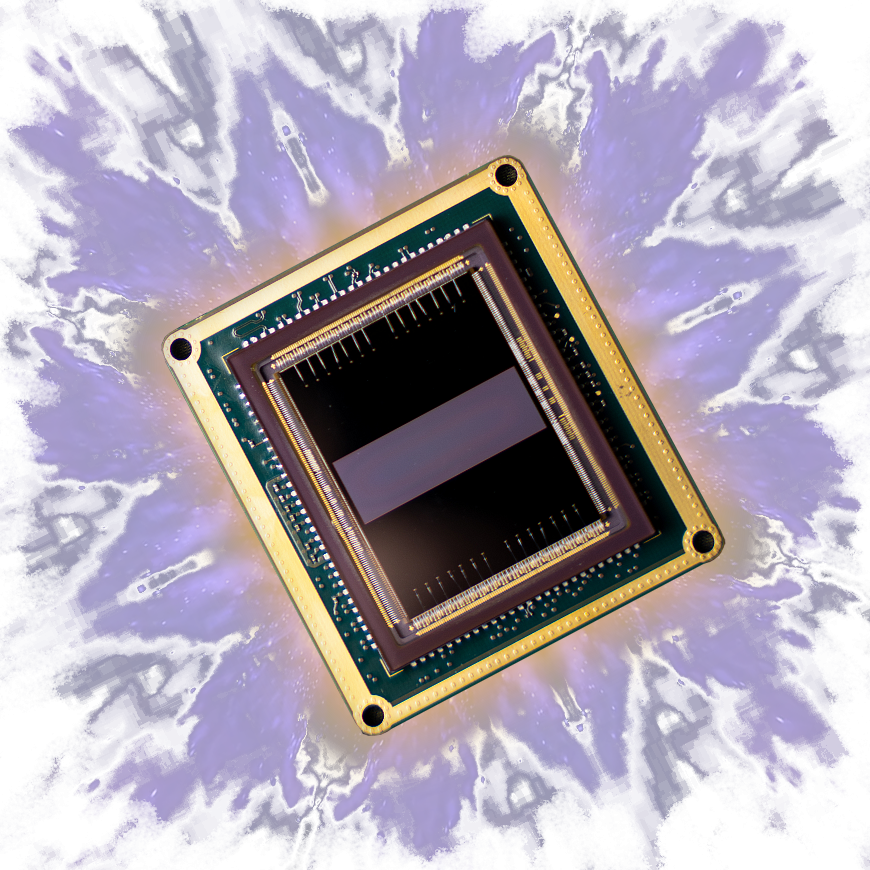

Exclusive imager design

-

Latest industry standards GigE Vision / GenICam 3D

-

3D profile pixel rate up to 128 megapixel/s

-

Internal processing rate up to 29 gigapixel/s

-

Unique features such as MultiPart and MultiPeak

3D Image Processing

Our 3D sensors combine extreme speed with high-precision resolution

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationC6 3070

The best 3D sensor chip

Warp Speed

Galactical speed

On-Sensor Chip Processing

Focus on relevant data transmission

MultiPart

Simultaneous output of multiple data sets

MultiPeak

Disturbance-free scans of reflective materials

REGION SEARCH UND REGION TRACKING

Secure detection and classification of the laser line

With the help of AT’s specially developed features, Region Search and Region Tracking, it is possible to reliably locate and determine the laser line as well as dynamically track and evaluate it as just one example of the wide range of capabilities our sensors have to offer. This enables a significant increase in scan speed while simultaneously utilizing the entire scanning height.

INTELLIGENT ALGORITHMS

Reliable definition of the laser line profile

Choose the appropriate model

| sku | Family | enabled | family | PN | PACK-groups | PACK-products | PACK-product_models | belongs_to_product_family-groups | belongs_to_product_family-products | belongs_to_product_family-product_models | integrated_components-groups | integrated_components-products | integrated_components-product_models | family_name-en_US | Model Name | WD | Z FoV | X FoV | Z Res. | X Res. | Wavelength | Class |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 202209007 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-39-82-172-SX-1G-405-2M | 172.5 | 15.0 | 81.3 | 0.6 | 19.9 | 405 | 2M | ||||||||||

| 202209008 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-39-145-172-SX-1G-405-2M | 172.5 | 15.0 | 148.5 | 0.6 | 36.3 | 405 | 2M | ||||||||||

| 202209010 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-39-82-172-SX-1G-405-3R | 172.5 | 15.0 | 81.3 | 0.5 | 19.9 | 405 | 3R | ||||||||||

| 202209011 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-39-145-172-SX-1G-405-3R | 172.5 | 15.0 | 148.6 | 0.8 | 36.3 | 405 | 3R | ||||||||||

| 202209012 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-39-82-172-SX-1G-405-3B | 172.5 | 15.0 | 81.3 | 0.5 | 19.9 | 405 | 3B | ||||||||||

| 202209013 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-39-145-172-SX-1G-405-3B | 172.5 | 15.0 | 148.8 | 0.6 | 36.3 | 405 | 3B | ||||||||||

| 202209014 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-39-82-172-SX-1G-660-2M | 172.5 | 15.0 | 81.3 | 0.5 | 19.9 | 660 | 2M | ||||||||||

| 202209015 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-39-145-172-SX-1G-660-2M | 172.5 | 15.0 | 148.5 | 0.7 | 36.3 | 660 | 2M | ||||||||||

| 202209016 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-39-82-172-SX-1G-660-3R | 172.5 | 15.0 | 81.3 | 0.5 | 19.9 | 660 | 3R | ||||||||||

| 202209017 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-39-145-172-SX-1G-660-3R | 172.5 | 15.0 | 148.5 | 0.7 | 36.3 | 660 | 3R | ||||||||||

| 202209018 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-39-82-172-SX-1G-660-3B | 172.5 | 15.0 | 81.3 | 0.5 | 19.9 | 660 | 3B | ||||||||||

| 202209019 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-39-145-172-SX-1G-660-3B | 172.5 | 15.0 | 148.5 | 0.7 | 36.3 | 660 | 3B | ||||||||||

| 202209020 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-35-7-31-SX-1G-405-2M | 31.0 | 3.0 | 6.4 | 0.2 | 5.0 | 405 | 2M | ||||||||||

| 202209021 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-35-7-31-SX-1G-405-3R | 31.0 | 3.0 | 6.4 | 0.1 | 5.0 | 405 | 3R | ||||||||||

| 202209022 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-35-7-31-SX-1G-450-3B | 31.0 | 3.0 | 6.4 | 0.1 | 5.0 | 450 | 3B | ||||||||||

| 202209023 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-35-12-31-SX-1G-405-2M | 31.0 | 8.0 | 12.1 | 0.3 | 9.4 | 405 | 2M | ||||||||||

| 202209024 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-35-12-31-SX-1G-405-3R | 31.0 | 8.0 | 12.1 | 0.3 | 9.4 | 405 | 3R | ||||||||||

| 202209025 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-35-12-31-SX-1G-450-3B | 31.0 | 8.0 | 12.1 | 0.2 | 9.4 | 450 | 3B | ||||||||||

| 202209026 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-25-20-72-SX-1G-405-2M | 72.0 | 20.0 | 18.1 | 0.3 | 14.1 | 405 | 2M | ||||||||||

| 202209027 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-25-20-72-SX-1G-405-3R | 72.0 | 20.0 | 18.1 | 0.3 | 14.1 | 405 | 3R | ||||||||||

| 202209028 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-25-20-72-SX-1G-450-3B | 72.0 | 20.0 | 18.1 | 0.4 | 14.1 | 450 | 3B | ||||||||||

| 202209029 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-21-40-90-SX-1G-405-2M | 90.0 | 46.0 | 39.0 | 1.3 | 30.5 | 405 | 2M | ||||||||||

| 202209030 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-21-40-90-SX-1G-405-3R | 90.0 | 46.0 | 39.0 | 0.9 | 30.5 | 405 | 3R | ||||||||||

| 202209031 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-21-40-90-SX-1G-405-3B | 90.0 | 46.0 | 39.0 | 0.6 | 30.5 | 405 | 3B | ||||||||||

| 202209032 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-21-53-90-SX-1G-405-2M | 90.0 | 46.0 | 52.5 | 0.9 | 25.6 | 405 | 2M | ||||||||||

| 202209033 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-21-53-90-SX-1G-405-3R | 90.0 | 46.0 | 52.5 | 1.0 | 25.6 | 405 | 3R | ||||||||||

| 202209034 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-21-53-90-SX-1G-405-3B | 90.0 | 46.0 | 52.5 | 1.3 | 25.6 | 405 | 3B | ||||||||||

| 202209035 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-100-106-SX-1G-405-2M | 106.0 | 60.0 | 106.0 | 1.2 | 51.8 | 405 | 2M | ||||||||||

| 202209036 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-100-106-SX-1G-405-3R | 106.0 | 60.0 | 106.0 | 1.7 | 51.8 | 405 | 3R | ||||||||||

| 202209037 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-100-106-SX-1G-405-3B | 106.0 | 60.0 | 106.0 | 1.4 | 51.8 | 405 | 3B | ||||||||||

| 202209038 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-100-106-SX-1G-660-2M | 106.0 | 60.0 | 106.0 | 1.3 | 51.8 | 660 | 2M | ||||||||||

| 202209039 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-100-106-SX-1G-660-3R | 106.0 | 60.0 | 106.0 | 1.4 | 51.8 | 660 | 3R | ||||||||||

| 202209040 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-100-106-SX-1G-660-3B | 106.0 | 60.0 | 106.0 | 1.4 | 51.8 | 660 | 3B | ||||||||||

| 202209041 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-14-100-197-SX-1G-405-2M | 197.0 | 110.0 | 100.4 | 4.0 | 49.0 | 405 | 2M | ||||||||||

| 202209042 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-14-100-197-SX-1G-405-3R | 197.0 | 110.0 | 100.4 | 3.7 | 49.0 | 405 | 3R | ||||||||||

| 202209043 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-14-100-197-SX-1G-405-3B | 197.0 | 110.0 | 100.4 | 3.0 | 49.0 | 405 | 3B | ||||||||||

| 202209044 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-14-100-197-SX-1G-660-2M | 197.0 | 110.0 | 100.4 | 2.4 | 49.0 | 660 | 2M | ||||||||||

| 202209045 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-14-100-197-SX-1G-660-3R | 197.0 | 110.0 | 100.4 | 2.4 | 49.0 | 660 | 3R | ||||||||||

| 202209046 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-14-100-197-SX-1G-660-3B | 197.0 | 110.0 | 100.4 | 2.5 | 49.0 | 660 | 3B | ||||||||||

| 202209047 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-63-106-SX-1G-405-2M | 106.0 | 40.0 | 63.0 | 0.8 | 30.8 | 405 | 2M | ||||||||||

| 202209048 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-63-106-SX-1G-405-3R | 106.0 | 40.0 | 63.0 | 1.4 | 30.8 | 405 | 3R | ||||||||||

| 202209049 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-63-106-SX-1G-405-3B | 106.0 | 40.0 | 63.0 | 0.9 | 30.8 | 405 | 3B | ||||||||||

| 202209050 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-63-106-SX-1G-660-2M | 106.0 | 40.0 | 63.0 | 1.0 | 30.8 | 660 | 2M | ||||||||||

| 202209051 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-63-106-SX-1G-660-3R | 106.0 | 40.0 | 63.0 | 1.0 | 30.8 | 660 | 3R | ||||||||||

| 202209052 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-63-106-SX-1G-660-3B | 106.0 | 40.0 | 63.0 | 1.0 | 30.8 | 660 | 3B | ||||||||||

| 202209053 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-38-106-SX-1G-405-2M | 106.0 | 30.0 | 37.5 | 1.0 | 18.3 | 405 | 2M | ||||||||||

| 202209054 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-38-106-SX-1G-405-3R | 106.0 | 30.0 | 37.5 | 0.7 | 18.3 | 405 | 3R | ||||||||||

| 202209055 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-38-106-SX-1G-405-3B | 106.0 | 30.0 | 37.5 | 0.8 | 18.3 | 405 | 3B | ||||||||||

| 202209056 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-38-106-SX-1G-660-2M | 106.0 | 30.0 | 37.5 | 0.8 | 18.3 | 660 | 2M | ||||||||||

| 202209057 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-38-106-SX-1G-660-3R | 106.0 | 30.0 | 37.5 | 0.8 | 18.3 | 660 | 3R | ||||||||||

| 202209058 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-23-38-106-SX-1G-660-3B | 106.0 | 30.0 | 37.5 | 0.8 | 18.3 | 660 | 3B | ||||||||||

| 202209059 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-75-106-SX-1G-405-2M | 106.0 | 40.0 | 79.3 | 1.4 | 58.5 | 405 | 2M | ||||||||||

| 202209060 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-75-106-SX-1G-405-3R | 106.0 | 40.0 | 79.3 | 1.5 | 58.5 | 405 | 3R | ||||||||||

| 202209061 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-75-106-SX-1G-405-3B | 106.0 | 40.0 | 79.3 | 1.2 | 58.5 | 405 | 3B | ||||||||||

| 202209062 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-75-106-SX-1G-660-2M | 106.0 | 40.0 | 79.3 | 1.5 | 58.5 | 660 | 2M | ||||||||||

| 202209063 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-75-106-SX-1G-660-3R | 106.0 | 40.0 | 79.3 | 1.6 | 58.5 | 660 | 3R | ||||||||||

| 202209064 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-75-106-SX-1G-660-3B | 106.0 | 40.0 | 79.3 | 1.3 | 58.5 | 660 | 3B | ||||||||||

| 202209065 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-47-106-SX-1G-405-2M | 106.0 | 40.0 | 47.0 | 0.7 | 36.7 | 405 | 2M | ||||||||||

| 202209066 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-47-106-SX-1G-405-3R | 106.0 | 40.0 | 47.0 | 0.7 | 36.7 | 405 | 3R | ||||||||||

| 202209067 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-47-106-SX-1G-405-3B | 106.0 | 40.0 | 47.0 | 1.0 | 36.7 | 405 | 3B | ||||||||||

| 202209068 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-47-106-SX-1G-660-2M | 106.0 | 40.0 | 47.0 | 0.7 | 36.7 | 660 | 2M | ||||||||||

| 202209069 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-47-106-SX-1G-660-3R | 106.0 | 40.0 | 47.0 | 0.7 | 36.7 | 660 | 3R | ||||||||||

| 202209070 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-47-106-SX-1G-660-3B | 106.0 | 40.0 | 47.0 | 0.7 | 36.7 | 660 | 3B | ||||||||||

| 202209071 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-29-106-SX-1G-405-2M | 106.0 | 35.0 | 28.0 | 0.6 | 21.9 | 405 | 2M | ||||||||||

| 202209072 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-29-106-SX-1G-405-3R | 106.0 | 35.0 | 28.0 | 0.7 | 21.9 | 405 | 3R | ||||||||||

| 202209073 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-29-106-SX-1G-405-3B | 106.0 | 35.0 | 28.0 | 0.6 | 21.9 | 405 | 3B | ||||||||||

| 202209074 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-29-106-SX-1G-660-2M | 106.0 | 35.0 | 28.0 | 0.6 | 21.9 | 660 | 2M | ||||||||||

| 202209075 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-29-106-SX-1G-660-3R | 106.0 | 35.0 | 28.0 | 0.6 | 21.9 | 660 | 3R | ||||||||||

| 202209076 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-23-29-106-SX-1G-660-3B | 106.0 | 35.0 | 28.0 | 0.6 | 21.9 | 660 | 3B | ||||||||||

| 202209077 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-14-160-197-SX-1G-405-2M | 197.0 | 120.0 | 163.1 | 6.8 | 79.6 | 405 | 2M | ||||||||||

| 202209078 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-14-160-197-SX-1G-405-3R | 197.0 | 120.0 | 163.2 | 3.7 | 79.6 | 405 | 3R | ||||||||||

| 202209079 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-14-160-197-SX-1G-405-3B | 197.0 | 120.0 | 163.2 | 3.6 | 79.6 | 405 | 3B | ||||||||||

| 202209080 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-14-160-197-SX-1G-660-2M | 197.0 | 120.0 | 164.2 | 4.3 | 79.6 | 660 | 2M | ||||||||||

| 202209081 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-14-160-197-SX-1G-660-3R | 197.0 | 120.0 | 164.2 | 3.6 | 79.6 | 660 | 3R | ||||||||||

| 202209082 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-14-160-197-SX-1G-660-3B | 197.0 | 120.0 | 164.1 | 4.1 | 79.6 | 660 | 3B | ||||||||||

| 202209083 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-14-76-197-SX-1G-405-2M | 197.0 | 80.0 | 75.1 | 2.1 | 58.7 | 405 | 2M | ||||||||||

| 202209084 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-14-76-197-SX-1G-405-3R | 197.0 | 80.0 | 75.1 | 2.1 | 58.7 | 405 | 3R | ||||||||||

| 202209085 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-14-76-197-SX-1G-405-3B | 197.0 | 80.0 | 75.1 | 2.3 | 58.7 | 405 | 3B | ||||||||||

| 202209086 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-14-76-197-SX-1G-660-2M | 197.0 | 80.0 | 75.1 | 2.1 | 58.7 | 660 | 2M | ||||||||||

| 202209087 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-14-76-197-SX-1G-660-3R | 197.0 | 80.0 | 75.1 | 2.1 | 58.7 | 660 | 3R | ||||||||||

| 202209088 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-14-76-197-SX-1G-660-3B | 197.0 | 80.0 | 75.1 | 2.1 | 58.7 | 660 | 3B | ||||||||||

| 202209097 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-30-182-400-SX-1G-405-2M | 400.0 | 150.0 | 180.7 | 1.7 | 44.1 | 405 | 2M | ||||||||||

| 202209098 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-30-182-400-SX-1G-405-3R | 400.0 | 150.0 | 180.7 | 2.0 | 44.1 | 405 | 3R | ||||||||||

| 202209099 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-30-182-400-SX-1G-405-3B | 400.0 | 150.0 | 180.7 | 1.7 | 44.1 | 405 | 3B | ||||||||||

| 202209100 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-30-182-400-SX-1G-660-2M | 400.0 | 150.0 | 180.7 | 1.7 | 44.1 | 660 | 2M | ||||||||||

| 202209101 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-30-182-400-SX-1G-660-3R | 400.0 | 150.0 | 180.7 | 1.7 | 44.1 | 660 | 3R | ||||||||||

| 202209102 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-30-182-400-SX-1G-660-3B | 400.0 | 150.0 | 180.7 | 1.6 | 44.1 | 660 | 3B | ||||||||||

| 202209103 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-30-288-400-SX-1G-405-2M | 400.0 | 250.0 | 290.1 | 2.6 | 70.8 | 405 | 2M | ||||||||||

| 202209104 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-30-288-400-SX-1G-405-3R | 400.0 | 250.0 | 290.1 | 2.6 | 70.8 | 405 | 3R | ||||||||||

| 202209105 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-30-288-400-SX-1G-405-3B | 400.0 | 250.0 | 290.1 | 2.1 | 70.8 | 405 | 3B | ||||||||||

| 202209106 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-30-288-400-SX-1G-660-2M | 400.0 | 250.0 | 290.1 | 2.1 | 70.8 | 660 | 2M | ||||||||||

| 202209107 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-30-288-400-SX-1G-660-3R | 400.0 | 250.0 | 290.1 | 2.7 | 70.8 | 660 | 3R | ||||||||||

| 202209108 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-4090-CS-30-288-400-SX-1G-660-3B | 400.0 | 250.0 | 290.1 | 2.2 | 70.8 | 660 | 3B | ||||||||||

| 202209110 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-30-330-400-SX-1G-405-2M | 400.0 | 300.0 | 328.8 | 5.0 | 160.5 | 405 | 2M | ||||||||||

| 202209111 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-30-330-400-SX-1G-405-3R | 400.0 | 300.0 | 328.8 | 6.5 | 160.5 | 405 | 3R | ||||||||||

| 202209112 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-30-330-400-SX-1G-405-3B | 400.0 | 300.0 | 328.8 | 4.3 | 160.5 | 405 | 3B | ||||||||||

| 202209113 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-30-330-400-SX-1G-660-2M | 400.0 | 300.0 | 328.8 | 6.3 | 160.5 | 660 | 2M | ||||||||||

| 202209114 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-30-330-400-SX-1G-660-3R | 400.0 | 300.0 | 328.8 | 5.1 | 160.5 | 660 | 3R | ||||||||||

| 202209116 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-30-248-400-SX-1G-405-2M | 400.0 | 200.0 | 248.9 | 3.8 | 194.5 | 405 | 2M | ||||||||||

| 202209117 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-30-248-400-SX-1G-405-3R | 400.0 | 200.0 | 248.9 | 4.9 | 194.5 | 405 | 3R | ||||||||||

| 202209118 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-30-248-400-SX-1G-405-3B | 400.0 | 200.0 | 248.9 | 3.8 | 194.5 | 405 | 3B | ||||||||||

| 202209119 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-30-248-400-SX-1G-660-2M | 400.0 | 200.0 | 248.9 | 3.8 | 194.5 | 660 | 2M | ||||||||||

| 202209120 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-30-248-400-SX-1G-660-3R | 400.0 | 200.0 | 248.9 | 4.9 | 194.5 | 660 | 3R | ||||||||||

| 202209121 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-1280-CS-30-248-400-SX-1G-660-3B | 400.0 | 200.0 | 248.9 | 4.3 | 194.5 | 660 | 3B | ||||||||||

| 202209122 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-18-1060-744-SX-1G-405-3R | 744.0 | 800.0 | 1,062.0 | 34.6 | 518.6 | 405 | 3R | ||||||||||

| 202209123 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-18-1060-744-SX-1G-405-3B | 744.0 | 800.0 | 1,062.0 | 32.4 | 518.6 | 405 | 3B | ||||||||||

| 202209124 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-18-1060-744-SX-1G-660-3R | 744.0 | 800.0 | 1,062.0 | 36.9 | 518.6 | 660 | 3R | ||||||||||

| 202209125 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-15-1290-920-SX-1G-405-3R | 920.0 | 1,090.0 | 1,294.3 | 78.9 | 632.0 | 405 | 3R | ||||||||||

| 202209126 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-15-1290-920-SX-1G-405-3B | 920.0 | 1,090.0 | 1,294.3 | 78.9 | 632.0 | 405 | 3B | ||||||||||

| 202209127 | CS Series | Yes | 3D Sensor | CS-1G | C6-S7-2040-CS-15-1290-920-SX-1G-660-3R | 920.0 | 1,090.0 | 1,294.3 | 63.5 | 632.0 | 660 | 3R | ||||||||||

| 602344992 | ECS Series | Yes | 3D Sensor | ECS-1G | cx2040 | C6-S7-2040-ECS-23-100-106-SX-1G-660-2M | 106.0 | 60.0 | 102.0 | 1.9 | 49.0 | 660 | 2M | |||||||||

| 602344993 | ECS Series | Yes | 3D Sensor | ECS-1G | cx2040 | C6-S7-2040-ECS-14-160-197-SX-1G-660-2M | 197.0 | 120.0 | 162.0 | 4.9 | 78.0 | 660 | 2M | |||||||||

| 602344994 | MCS Series | Yes | 3D Sensor | MCS-1G | cx3070 | C6-S7-3070-MCS-15-1380-1100-DX-1G-660-3R | 1,107.0 | 799.0 | 1,359.0 | 24.2 | 442.4 | 660 | 3R | |||||||||

| 602344997 | XCS Series | Yes | 3D Sensor | XCS-1G | cx4090,SL-405-155-RTV-M-20-S03-SDAT4-3B-I2C-24V | C6-S7-4090-XCS-28-53-146-DX-1G-405-3R | 146.0 | 10.0 | 53.3 | 0.4 | 13.0 | 405 | 3R | |||||||||

| 602344998 | XCS Series | Yes | 3D Sensor | XCS-1G | cx4090,SL-405-155-RTV-M-20-S03-SDAT4-3B-I2C-24V | C6-S7-4090-XCS-28-53-146-SX-1G-405-3R | 146.0 | 10.0 | 53.2 | 0.0 | 13.0 | 405 | 3R | |||||||||

| 602344999 | XCS Series | Yes | 3D Sensor | XCS-1G | cx3070W,SL-405-155-RTV-M-20-S03-SDAT4-3B-I2C-24V | C6-S7-3070W-XCS-28-48-146-DX-1G-405-3R | 146.0 | 20.0 | 47.9 | 0.5 | 15.6 | 405 | 3R | |||||||||

| 602345000 | XCS Series | Yes | 3D Sensor | XCS-1G | cx3070W,SL-405-155-RTV-M-20-S03-SDAT4-3B-I2C-24V | C6-S7-3070W-XCS-28-48-146-SX-1G-405-3R | 146.0 | 20.0 | 47.9 | 0.0 | 15.6 | 405 | 3R | |||||||||

| 602345001 | XCS Series | Yes | 3D Sensor | XCS-1G | cx3070,SL-405-155-RTV-M-20-S03-SDAT4-3B-I2C-24V | C6-S7-3070-XCS-28-48-146-DX-1G-405-3R | 146.0 | 20.0 | 47.9 | 0.5 | 15.6 | 405 | 3R | |||||||||

| 602345002 | XCS Series | Yes | 3D Sensor | XCS-1G | cx3070,SL-405-155-RTV-M-20-S03-SDAT4-3B-I2C-24V | C6-S7-3070-XCS-28-48-146-SX-1G-405-3R | 146.0 | 20.0 | 45.4 | 0.0 | 14.8 | 405 | 3R | |||||||||

| 602345006 | MCS Series | Yes | 3D Sensor | MCS-1G | cx4090 | C6-S7-4090-MCS-30-180-400-SX-1G-660-3R | 403.0 | 150.0 | 180.8 | 0.0 | 44.1 | 660 | 3R | |||||||||

| 602345022 | MCS Series | Yes | 3D Sensor | MCS-1G | cx4090 | C6-S7-4090-MCS-30-490-680-SX-1G-660-3R | 680.0 | 350.0 | 498.9 | 0.0 | 121.9 | 660 | 3R | |||||||||

| 602345096 | MCS Series | Yes | 3D Sensor | MCS-1G | cx4090 | C6-S7-4090-MCS-30-490-680-SX-1G-660-2M | 680.0 | 300.0 | 498.9 | 0.0 | 121.8 | 660 | 2M | |||||||||

| 602345151 | MCS Series | Yes | 3D Sensor | MCS-1G | cx1280 | C6-S7-1280-MCS-15-1240-1180-SX-1G-660-2M | 1,180.0 | 500.0 | 1,252.6 | 0.0 | 978.6 | 660 | 2M | |||||||||

| 602345194 | MCS Series | Yes | 3D Sensor | MCS-1G | cx1280 | C6-S7-1280-MCS-20-130-330-SX-1G-660-3B | 338.0 | 310.0 | 135.3 | 0.0 | 105.7 | 660 | 3B | |||||||||

| 602345195 | MCS Series | Yes | 3D Sensor | MCS-1G | cx2040 | C6-S7-2040-MCS-20-480-650-SX-1G-660-3R | 655.0 | 400.0 | 481.7 | 0.0 | 235.2 | 660 | 3R | |||||||||

| 602345210 | MCS Series | Yes | 3D Sensor | MCS-1G | cx4090 | C6-S7-4090-MCS-20-420-530-DX-1G-660-3R | 536.0 | 400.0 | 419.9 | 5.5 | 102.5 | 660 | 3R | |||||||||

| 602345212 | MCS Series | Yes | 3D Sensor | MCS-1G | cx4090 | C6-S7-4090-MCS-15-1130-820-SX-1G-405-3B | 827.0 | 299.0 | 1,116.9 | 0.0 | 272.7 | 405 | 3B | |||||||||

| 602345238 | MCS Series | Yes | 3D Sensor | MCS-1G | cx1280 | C6-S7-1280-MCS-15-80-350-SX-1G-660-3R | 359.0 | 160.0 | 81.2 | 0.0 | 63.4 | 660 | 3R | |||||||||

| 602345247 | MCS Series | Yes | 3D Sensor | MCS-1G | cx1280 | C6-S7-1280-MCS-25-120-350-SX-1G-660-3R | 356.0 | 100.0 | 126.7 | 0.0 | 99.0 | 660 | 3R | |||||||||

| 602345288 | MCS Series | Yes | 3D Sensor | MCS-1G | cx4090 | C6-S7-4090-MCS-20-490-740-SX-1G-405-3B | 742.0 | 650.0 | 497.8 | 0.0 | 121.5 | 405 | 3B | |||||||||

| 602345304 | MCS Series | Yes | 3D Sensor | MCS-1G | cx2040 | C6-S7-2040-MCS-15-1000-990-SX-1G-660-3R | 992.0 | 799.5 | 1,006.9 | 0.0 | 491.7 | 660 | 3R | |||||||||

| 602345312 | MCS Series | Yes | 3D Sensor | MCS-1G | cx4090 | C6-S7-4090-MCS-25-310-460-SX-1G-405-3B | 465.0 | 200.0 | 318.6 | 0.0 | 77.8 | 405 | 3B | |||||||||

| 602345471 | ECS Series | Yes | 3D Sensor | ECS-1G | cx4090 | C6-S7-4090-ECS-30-284-400-SX-1G-660-2M | 400.0 | 250.0 | 284.1 | 2.1 | 70.9 | 660 | 2M | |||||||||

| 602345472 | ECS Series | Yes | 3D Sensor | ECS-1G | cx4090 | C6-S7-4090-ECS-18-575-744-SX-1G-660-2M | 744.2 | 500.0 | 576.1 | 7.0 | 140.5 | 660 | 2M | |||||||||

| 602345542 | ECS Series | Yes | 3D Sensor | ECS-1G | cx4090 | C6-S7-4090-ECS-18-1020-744-SX-1G-660-2M | 744.2 | 700.0 | 1,020.0 | 12.6 | 249.0 | 660 | 2M | |||||||||

| Family | WD | Z FoV | X FoV | Wavelength | Class |

Technical Data

-

General technical data

(*) Availability of feature might vary with type of sensorHigh dynamic range features: Multiple Slope Mode 3D algorithms: MAX, TRSH, COG, FIR PEAK* 3D scan features: Automatic Region Tracking, Automatic Region Search, Multiple Regions*, AutoStart Connections 17 pin, M12 Power I/O

8pin, M12 EthernetData interface Gigabit Ethernet (1Gbit/s) Standards GigE Vision with GenICam Temperature Operation 0°C to +40°C

Storage -20°C to +80°CProtection class IP67 Electrical specifications

Power consumption max. 15 W Power supply sensor 10-24 V DC (max. 27 V DC) Power supply laser 10-24 V DC I/O specifications

Digital Input: 2 electrial isolated inputs, +5V to +24V DC Digital Output: 2 electrical isolated outputs, +5 to +24V DC (max. 100 mA) Encoder/Resolver Input: A+, A-, B+, B-, Z+, Z- High-Speed Triple RS-422 Receiver Max. input voltage +5V DC (TTL level) -

(*) Not available for C6-3070W

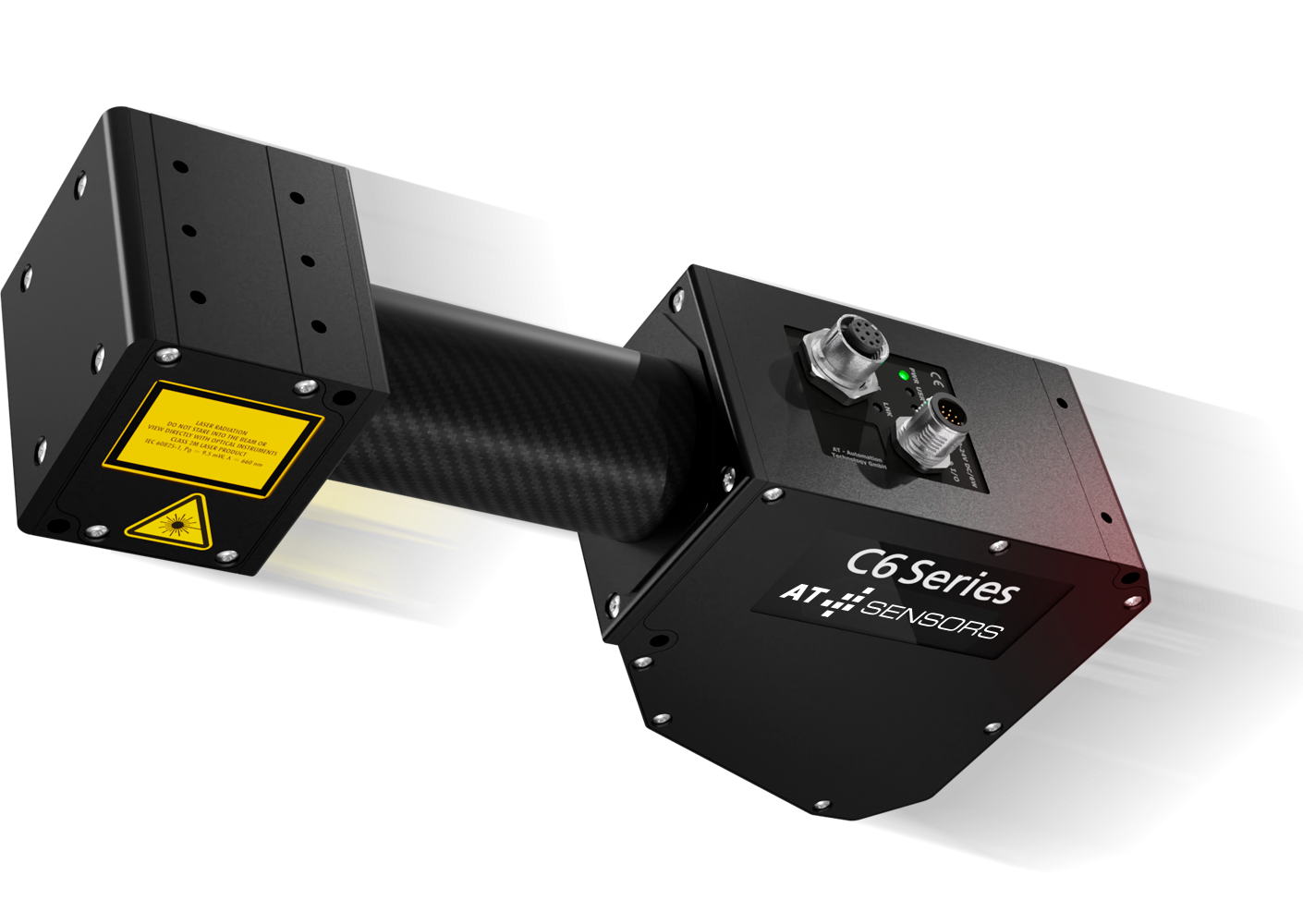

Sensors in comparison

C6-1280 C6-2040 C6-3070 C6-3070W C6-4090 Sensor type CMOS Shutter type Global shutter Resolution (H xV) 1280 x 1024 Pixel 2048 x 1088 Pixel 3072 x 1020 Pixel 3072 x 1020 Pixel 4096 x 3072 Pixel Pixel size 6.6 µm x 6.6 µm 5.5 µm x 5.5 µm 6.6 µm x 6.6 µm 6.6 µm x 6.6 µm 5.5 µm x 5.5 µm Sensor size 8,448 mm x 6,758 mm 11,264 mm x 5,984 mm 20,275 mm x 6,632 mm 20,275 mm x 6,732 mm 22,528 mm x 16,896 mm Image circle 10,82 mm 12,75 mm 21,37 mm 21,37 mm 28,16 mm Sensor format 2/3″ 2/3″ 1,5″ 1,5″ 1,75″ Power consumption max. 15 W ADC resolution 12 bit 10 bit 10 bit 10 bit 10 bit Extended dynamic range Up to 90 dB with activated Multi Slope Mode Scan 3D extraction process MAX, TRSH, COG, FIR PEAK* High dynamic range imaging Multi Slope Mode 3D features Multipeak, Multipart, Multiple Regions*, Region Tracking/Search, Autostart Typical Profile Speed Depending on Number of Sensor Rows (Hz)*

*Internal values. The actual usable profile speed may be limited by the 1 Gbit/s interface. C6-1280 C6-2040 C6-3070 C6-3070W C6-4090 Sensor Rows With 1280 pixel profile width With 688 pixel profile width Sensor Rows Sensor Rows Sensor Rows Sensor Rows 4 121130 172744 4 43478 6 66489 6 204918 4 24875 8 84034 128388 8 18604 12 47846 12 176678 8 20352 16 52114 84825 16 13289 24 30656 24 138504 16 14925 32 29615 50533 32 8456 48 17838 48 96712 32 9733 64 15893 27941 64 4895 96 9714 96 60314 64 5740 128 8249 14751 128 2657 192 5083 192 34412 128 3153 256 4204 7587 256 1388 384 2602 384 18512 256 1658 512 2123 3849 512 710 768 1317 768 9621 512 851 1024 1067 1938 1088 338 1020 994 1020 7315 1024 431 3072 145