/ Applications / Battery Inspection

Battery Inspection

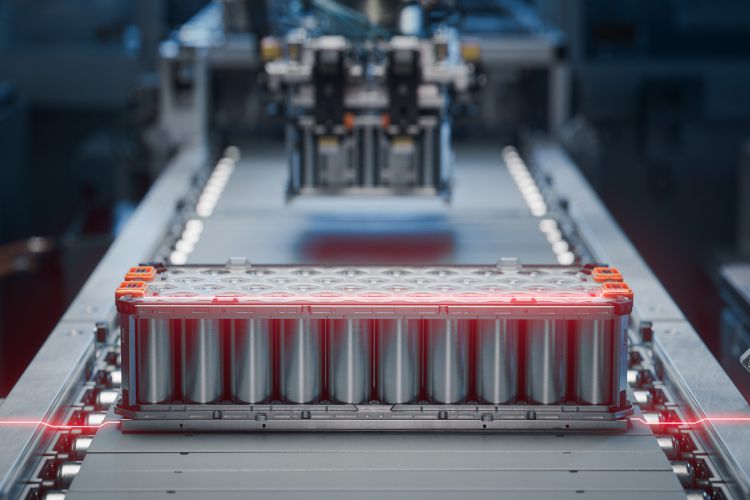

Battery Inspection In the electronics industry, precision is of the utmost importance, especially when it comes to battery inspection. The C6-4090CS is a crucial step towards error-free production and ensures the highest quality through its outstanding specifications. If you are looking for the best instrument for battery inspection, you should consider the C6-4090CS.

Precise Battery Inspection for Reliable Batteries

Battery quality control is a crucial element in the electronics industry. AT – Automation Technology provides the ideal solution for this task with the C6-4090CS 3D profile sensor.

Challenge

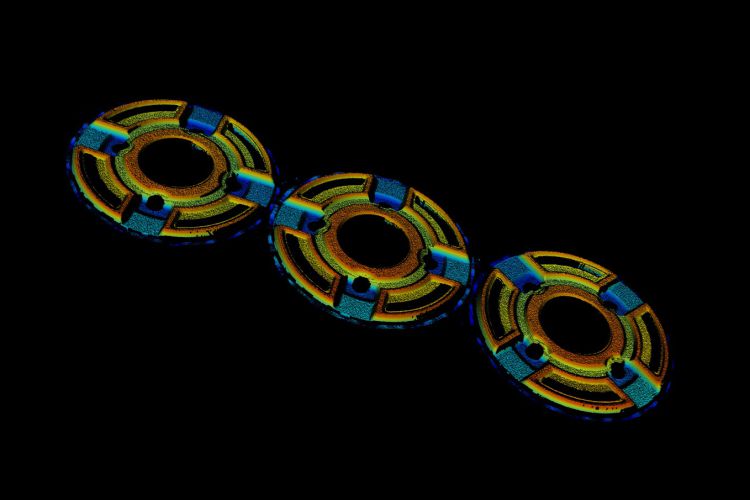

Battery inspection requires high-resolution and fast sensors because quality control must determine whether all layers within the battery are in the correct position to rule out potential short circuits. A large field of view (FOV) is needed for this inspection to enable comprehensive quality assurance.

Solution

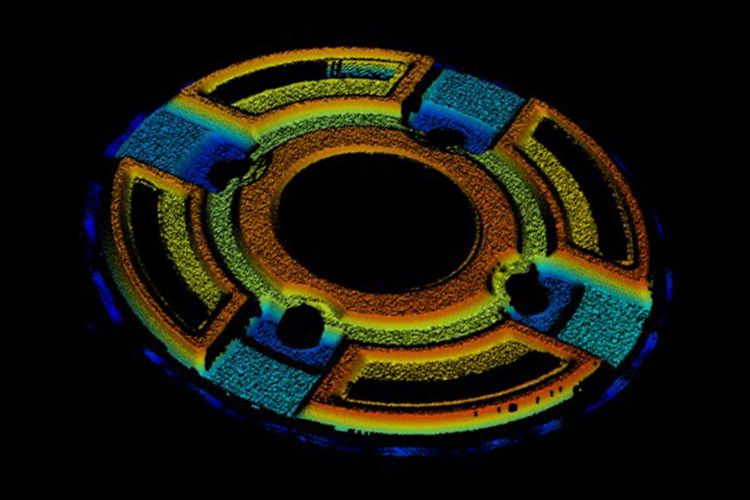

The C6-4090CS 3D profile sensor from AT excels in meeting these requirements. With a 4K sensor (4090 pixels) and high resolution, it offers precise and fast inspection. Additionally, with its large FOV, it covers comprehensive quality assurance.

Your Benefits

Field of View

A large Field of View (FOV) enables comprehensive quality inspections.

High-Speed

High speed and accuracy ensure fast and precise inspections.

Präzision

A 4K sensor with high resolution provides detailed results.

Need advice on options? Let us guide you.