3D Tire Inspection

Guaranteed Safety through Reliable Tire Inspection

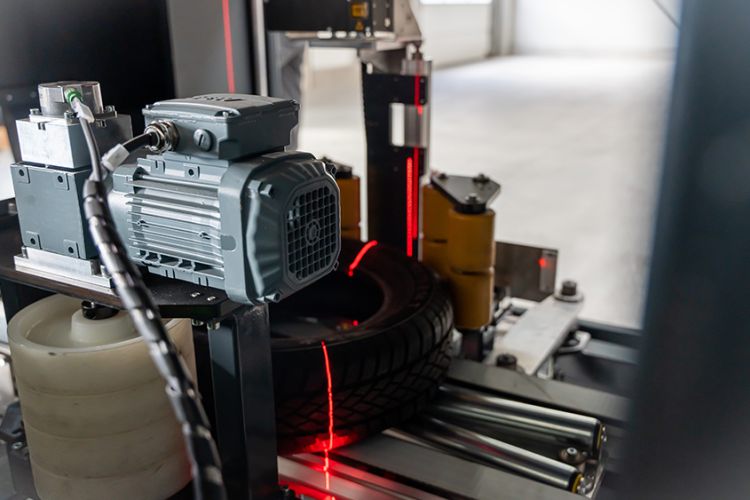

Quality assurance plays a critical role in the automotive industry, and with our C6-1280CS 3D laser triangulation sensors, manufacturers can now achieve unparalleled precision and speed. Every aspect of the manufacturing process is monitored and evaluated to ensure the highest quality standards are met.

Effective Process Optimization

Our sensors also offer effective process optimization by providing real-time data that allows manufacturers to identify weaknesses and streamline production flow. By minimizing downtime and maximizing efficiency, automotive manufacturers can increase production capacity while reducing costs.

Lower Costs

With our technology, you’ll be ready for the challenges of the modern automotive industry. Our 3D sensors give you a competitive advantage by helping you produce high-quality vehicles more efficiently and at lower costs.