Can Check

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

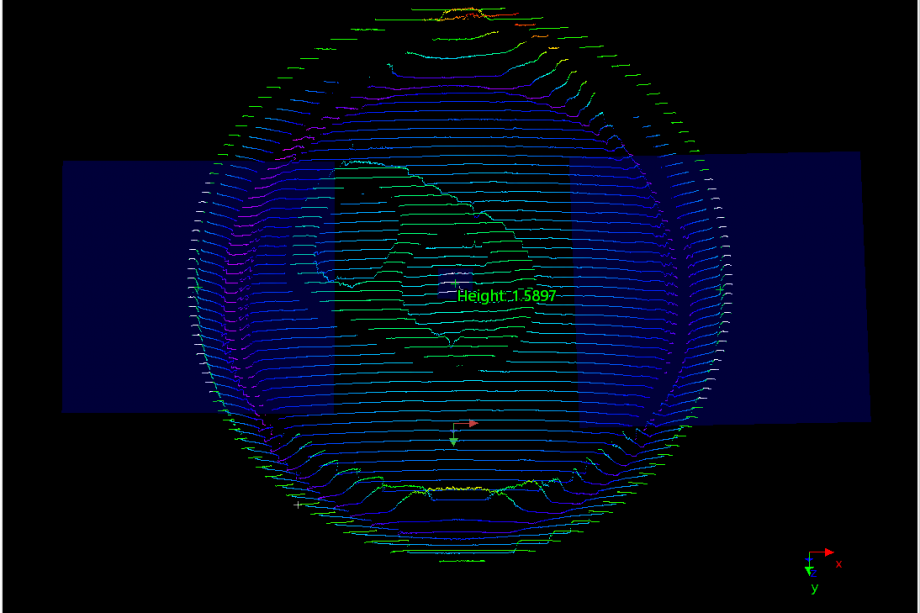

Piecework Filling Inspection: Checking 2,400 Cans per Minute

In the beverage industry, fill volume and pressure control are crucial to prevent quality issues and production downtime. AT Sensors and EVT developed a 3D scanning solution that uses the CS 2040 3D sensor to detect defective cans directly on the conveyor belt—at a speed of up to 3.5 million cans per day.

Challenge

The biggest challenge in developing the Can Check application was to inspect the pressure of cans directly on the conveyor belt using a 3D scan—at an extreme speed of up to 3.5 million cans per day. At the same time, the system needed to be highly precise, reliable, and seamlessly integrable into existing production lines to prevent downtime and optimize quality control.

Solution

AT and EVT developed a high-precision 3D scanning solution that uses the CS 2040 3D sensor to measure can pressure directly on the conveyor belt. With integrated real-time data processing and a specialized tracking system, defective cans are detected and removed within milliseconds—at an impressive speed of up to 3.5 million cans per day. This combination of precision, speed, and seamless integration has ensured uninterrupted 24/7 operation for over eight years.

Application Examples