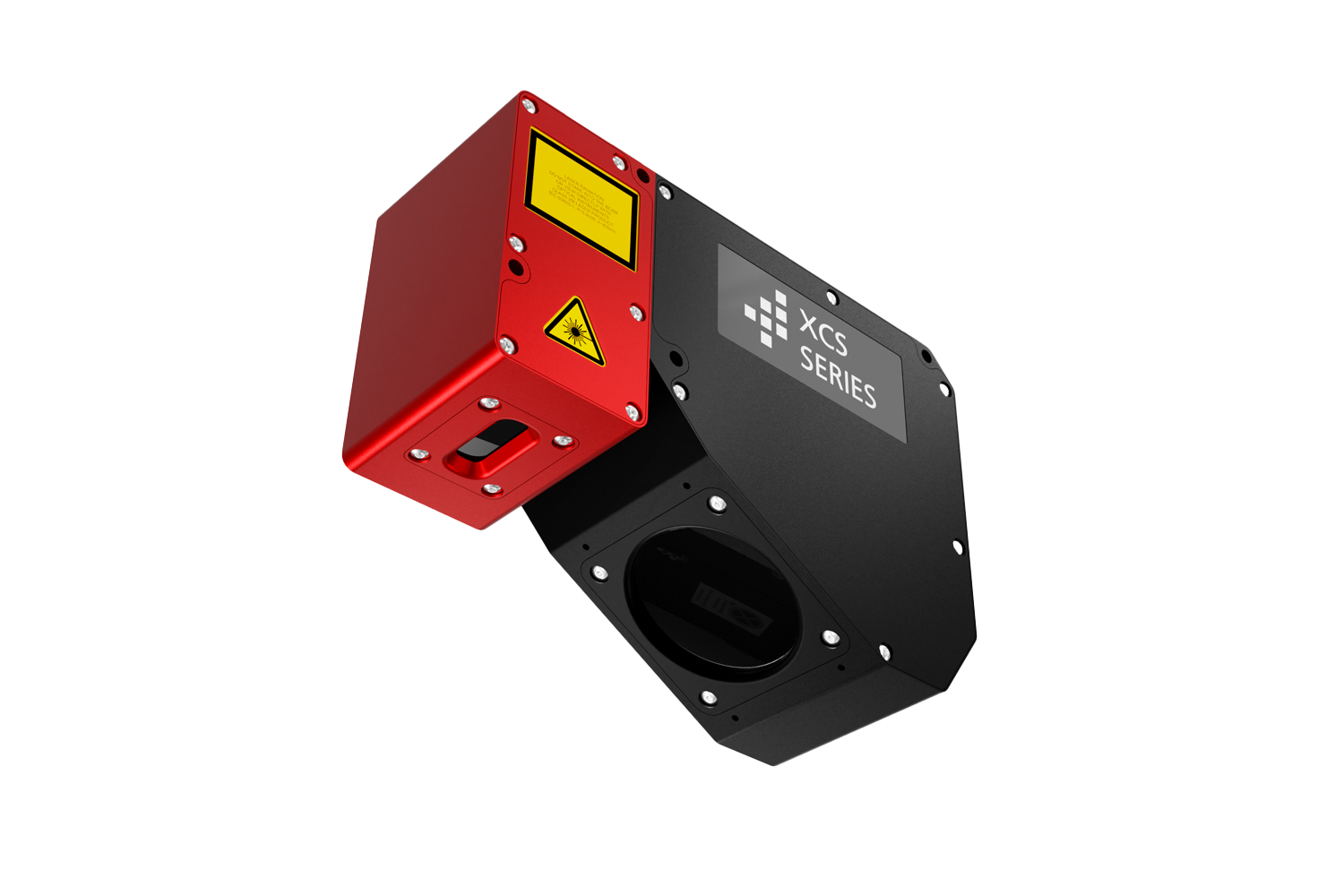

High-Precision 3D Sensor

- Integrated 3D Sensor C6 Series

- Unique 3D scan results without occlusion due to dual-head option and extremely high resolution

- High precision and repeatability thanks to high-quality laser line projection

- Unrivaled optical resolution for electronic inspection (e.g. BGA inspection) with a field of view of up to 53 mm

- Highest inspection speed available with 3070 WARP sensor

Please log in or register to view prices or buy products.

High-Precision 3D Sensors

With the new 3D sensor from the XCS series, AT – Automation Technology is launching a product that is particularly suitable for high-performance applications in the electronics industry thanks to its enormous precision and extreme speed. The sensor is characterized by an optimized laser with homogeneous thickness along the laser line, which guarantees precise detection of even the smallest structures. This enables high-precision inspection applications with high repeatability, which is ideal for the inspection of ball grid arrays (BGAs), among other things. The innovative clean beam function protects the laser from external interference and ensures a uniform intensity distribution, which further increases reliability. The sensor’s dual-head option eliminates occlusions and achieves profile speeds of up to 140 kHz with the 3070 WARP version, speeding up data analysis and increasing efficiency.

Application recommendation

- Electronics & Semicon

- eMobility & Battery

- Automotive Metrology

- Industrial Automation

- Welding

- Pharmaceuticals

- Wood & Lumber

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information