Piecework Filling Inspection: Checking 2,400 Cans per Minute

- 3D sensor must react flexibly to different surface structures

- Can check application impresses with highest flexibility at maximum speed

- Development of the application using software from EVT Eye Vision Technology GmbH and 3D sensors from AT – Automation Technology GmbH for leading mechanical engineering company in the beverage industry

What is the decisive sound when opening a beverage can? The hiss! This not only stands for freshness, but above all for a guarantee of quality. However, the fact that the can fizzes properly at all is no coincidence, but has to do with the exact filling quantity and the correct filling pressure. [sc_image position=”centered” disable_lightbox=”1″ src=”/8831″]In order to check whether the filling quantity and filling pressure comply with the specified standard, AT – Automation Technology GmbH (AT), together with EVT Eye Vision Technology GmbH (EVT), has developed an application for a leading global company for filling machines, which inspects and evaluates so-called beverage containers with the aid of a 3D scan. And it works at an impressive speed in a 24/7 operation: 40 cans per second, 2,400 cans per minute, 3.5 million cans per day.

That’s how high the cadence is from just one of these filling machines, which are used on a daily basis in the US by a world-renowned beverage manufacturer. However, it is not only the high frequency that makes this application so special, which was specially developed for the beverage industry. It has been running so successfully for eight years that the customer recently reordered triple-digit quantities of 3D sensors in the summer of 2021 in order to equip several hundred more filling machines with them. The major advantages of the application for can check: reliable inspection software that can easily work with AT’s highly accurate and very fast 3D sensors, which have been in use for many years without malfunction. This means that the application can be easily implemented in any new filling machine at any time according to the plug & play principle.[sc_image position=”centered” src=”/8833″]Downgrade Rather than Upgrade when Using 3D Sensor Technology

“Actually, we have to constantly develop our software further in order to keep up with the faster processors and production processes. With the can check application, however, it’s exactly the opposite. Sometimes we even have to downgrade the 3D sensors so that nothing changes in the application and the entire system might have to be re-qualified,” explains Michael Beising, Managing Director of EVT.

In fact, the application works so well that in normal operation, at most one can per day has to be rejected due to a faulty surface finish. The conveyor belt was specially equipped with a tracker for pressure control, which is in turn connected to the 3D camera. If the camera transmits a 3D point cloud that deviates from the norm, the can is removed from the conveyor belt by compressed air within milliseconds.[sc_image position=”centered” src=”/8835″]3D Scan for Can Check Requires Highest Precision and Flexibility

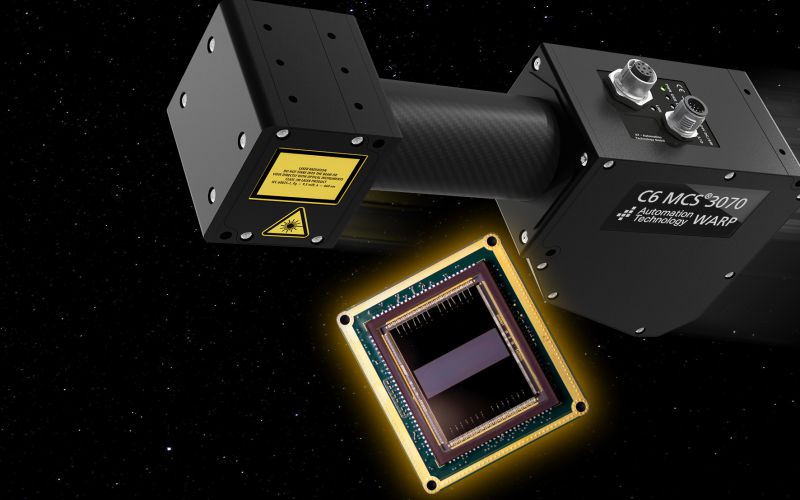

AT had decided to use 3D compact sensors of the type C5-2040CS-23-100 for this application. These are very precise with a resolution of 2,048 points per profile and at the same time impress with an enormous speed of 25,000 profiles per second. Also worth mentioning is the wide 100 millimeter field of view of this model. This allows the sensor to react flexibly to the position of the can on the conveyor belt. “For 20 years now, we have been among the manufacturers of the world’s fastest 3D sensors, which are also equipped with standard interfaces such as GigE Vision, GenICam and now even GenICam 3D. Customer benefit is always a priority for us, in addition to processing only high-quality technology, as we always focus on long-term cooperation in our customer relationships,” says Michael Wandelt, CEO of AT. And EVT CEO Michael Beising adds: “The colleagues at AT have a great deal of know-how and already knew very well which 3D sensors would be best suited for this application. Thus, all prerequisites for the reliable output of precise point clouds were given, because these always form the basis for good image processing.”

Application for Can Check Has Been Running Without Errors for Eight Years

Incidentally, the decisive factor for the development of the can check in 2013 was poor quality management. The beverage manufacturer was repeatedly faced with the problem of short downtimes during the filling process due to, for example, faulty curvatures of the can surface. In order to eliminate these downtimes, to optimize the inspection process, and to significantly increase the can production, the beverage manufacturer hoped to achieve profitable success by developing an application for inspecting can pressure. The challenge was to inspect the pressure of the cans directly on the conveyor belt via a 3D scan and to do so at maximum speed. And it is precisely this challenge that EVT and AT have been reliably meeting for eight years now.[sc_image position=”centered” src=”/8837″]