Inspection of Baked Goods

Quality Check of 100,000 rolls per hour!

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Checking 100,000 Rolls Per Hour: Perfect Baked Goods in Record Time

Especially in industrial baked goods, today’s consumers expect consistently perfect results: uniform shape, optimal baking, and a recognizable appearance every time. These rising expectations present new challenges for producers – particularly when working at high throughput. Reliable, automated quality control is becoming a key factor for maintaining competitiveness.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationMaximum Process Optimization

Precise Quality Control

Automated Sorting Process

Bread rolls are no longer just an affordable staple – they’ve become a promise of quality.

In the federal state of Schleswig-Holstein, a normal sliced bread roll now costs between €0.40 and €0.60 on average. The prices for special rolls such as grain rolls or pretzel sticks are sometimes significantly higher. This price trend has led to a massive increase in expectations of the quality of industrially produced baked goods. Both producers and consumers demand consistent results in terms of appearance and taste. While supermarket chains want to retain their customers through consistent product quality, consumers are increasingly paying attention to every detail as prices rise. Today, a bread roll should not only be fresh and crispy, but should also always look and taste the same.

With this in mind, system integrator ISW and technology company AT Sensors joined forces to develop a high-performance application for the automated quality control of baked goods. The aim was to create a solution that can simultaneously detect and evaluate a wide range of quality characteristics at high throughput and without a clocked process. The initial impetus for the project came from Ilapak, an internationally active machine manufacturer headquartered in Europe that develops and produces packaging lines and baking lines for large industrial customers. These are used by retail giants such as supermarket chains.

Tradition meets technology: Ilapak embraces 3D sensor technology

As a long-standing manufacturer of baking lines, Ilapak is a key partner for many large bakeries worldwide. The company’s systems are characterized by their high robustness, scalability and speed. Ilapak was founded in Switzerland in 1970 and has since developed into a global supplier of packaging machines. Its specialization in flexible packaging solutions has made Ilapak a partner to many food manufacturers who value not only productivity but also quality. In order to set new standards in quality assurance, Ilapak wanted to upgrade its systems with modern 3D image processing.

Previously, only line scan cameras with 2D technology were used there. These only provided simple shadow images of the baked goods and could not provide any information on the exact geometry, surface structure or distribution of details. However, this is precisely what end customers are increasingly demanding: Detailed information about shape, structure, elevations, volume distribution or topping placement. A requirement that could only be met with 3D sensor technology.

AT Sensors – a northern German company specializing in 3D laser triangulation sensors with over 25 years of experience – had the right technology. The company develops and manufactures its sensors in Germany and specializes in solutions that require both speed and maximum precision. The sensors are used in the automotive, packaging, food and electronics industries, among others. In addition to the high resolution, their unique selling points are above all the flexibility in customization and the large number of integrated functions that make it possible to solve even complex measuring tasks.

ISW, on the other hand, has been an established system integrator for industrial image processing solutions for over a decade. Just like AT, based in northern Germany, ISW serves customers from various sectors, with a focus on the food, automation and packaging industries. The company specializes in the integration of hardware components such as cameras and sensors into existing production processes as well as the development of tailor-made software solutions for industrial image evaluation. ISW is one of the few providers on the market that can supply complete systems from a single source.

Challenge

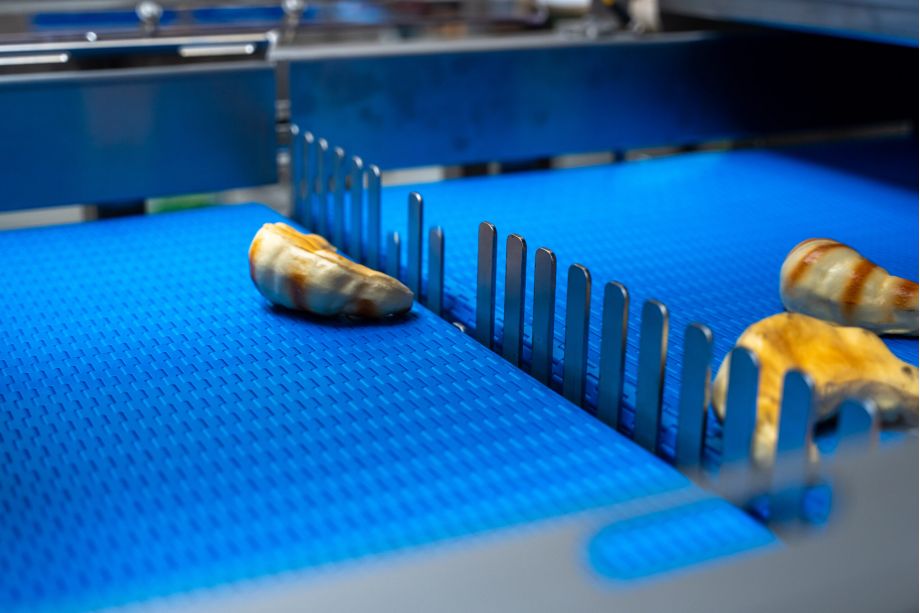

The baked goods are inspected directly on the conveyor belts of the Ilapak systems – without a timed process sequence. Several quality parameters have to be checked at the same time: These include dimensions such as height and size, cutting characteristics and specific surface properties such as the distribution of cheese on lye pastries. Such complex inspection tasks exceed the capabilities of conventional 2D image processing systems and therefore require the use of advanced 3D sensor technology.

“The production lines pass up to 100,000 bread rolls per hour, which are neither organized nor all next to each other, but rather partly on top of each other. The conveyor belts are also wider than one meter, so the sensor we were looking for had to have a wide field of view and a high resolution,” reports ISW Managing Director Tobias Wichmann. He also explains that the inertia of the conveyor belts was a difficult factor during application development. “The industrial baking lines operate 24/7 and must not be interrupted. The large baking lines are programmed in such a way that they sometimes have an hour’s lead time if changes need to be made. This is the only way to avoid losses and system damage,” mentions Wichmann.

Solution

The requirements of Ilapak and ISW were therefore correspondingly high: to find a sensor manufacturer that not only met the technical requirements, but could also be used reliably in industry. And this is precisely where AT Sensors came into play, offering the ideal solution with its modular MCS 2040 3D sensor.

A key feature of the MCS series is its modular design, which makes the sensors the perfect solution for a wide range of applications. “The MCS stands for maximum flexibility: thanks to almost unlimited configuration options, we build sensors that are precisely tailored to the respective application – whether cost-optimized or high-performance. Our aim is not to supply just any sensor, but exactly the right one. Because once you’ve worked with AT, you stay with AT,” reports AT Sensors Head of Sales Dr.-Ing. Athinodoros Klipfel.

In fact, with the MCS series, each sensor can be individually adapted to the specific requirements of the application – without additional costs, without minimum purchase quantities and without long delivery times. At the same time, the sensors have standardized interfaces such as GigE Vision, which considerably simplifies integration into existing systems.

Each conveyor line was therefore equipped with its own sensor, which has since enabled high-precision measurement of the baked goods during operation. The MCS 2040 records 2048 measuring points per profile and achieves a resolution of 0.5 millimetres in the X-axis and an impressive 0.03 millimetres in the Z-axis. A particularly large field of view of 1000 millimetres and a profile speed of up to 25 kilohertz ensure fast and continuous data acquisition even at very high throughput rates.

A red laser with a wavelength of 660 nanometers is used, which delivers a particularly high intensity to the detector and therefore enables extremely sensitive and precise measurement. In addition, the MultiPeak and MultiPart functions developed by AT Sensors enable the simultaneous detection and evaluation of several quality features, allowing a comprehensive geometric and structural analysis of the products in real time.

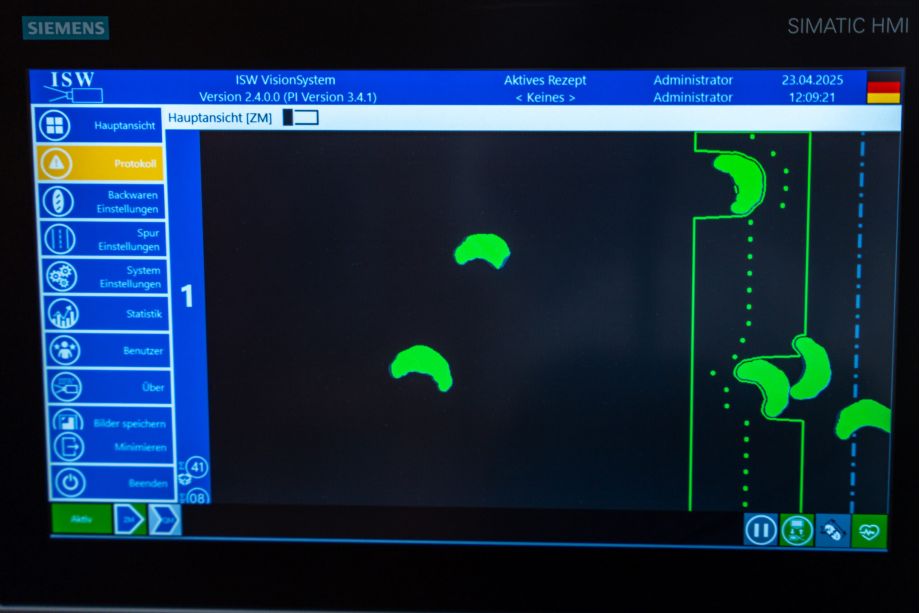

The captured 3D data is then processed using the software developed by ISW, which is based on the powerful HALCON image processing library. The processed information is forwarded directly to the programmable logic controller (PLC), where it controls the sorting mechanisms of the packaging system. This allows the baked goods to be packaged specifically according to defined quality and quantity specifications for the retail trade.

Application Examples