Modular 3D Sensor

- Integrated 3D Sensor C6 Series

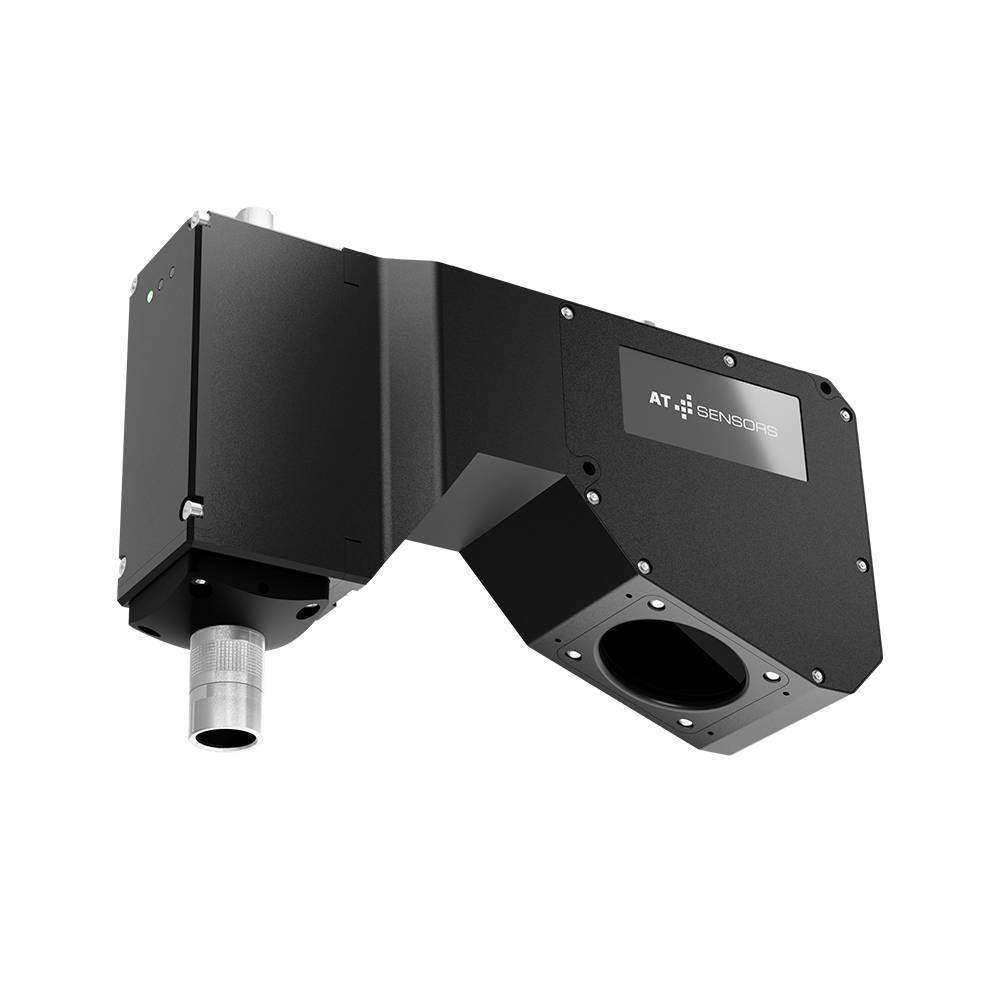

- Modular sensor concept for individual solutions

- Flexibly adaptable to customer requirements

- Available as Standard and High Power Laser

- No extra costs

- No long delivery times

- No minimum order quantities

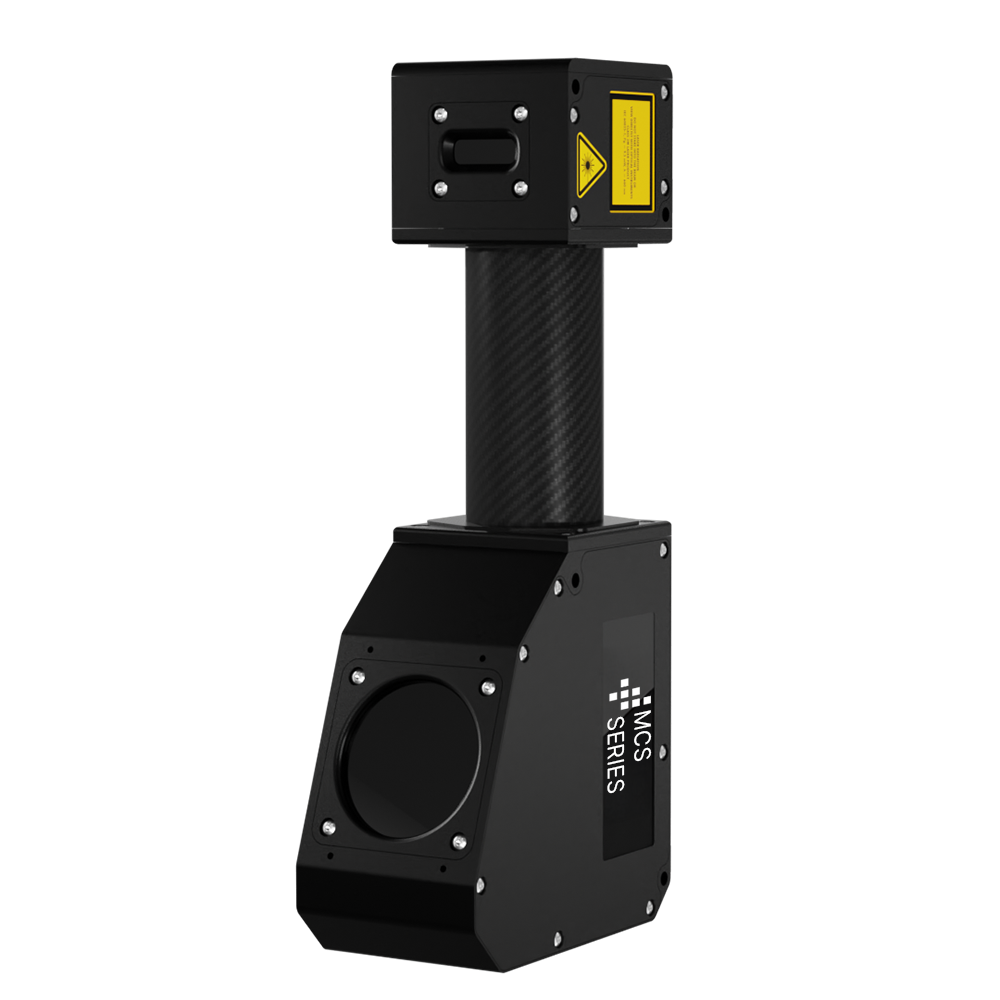

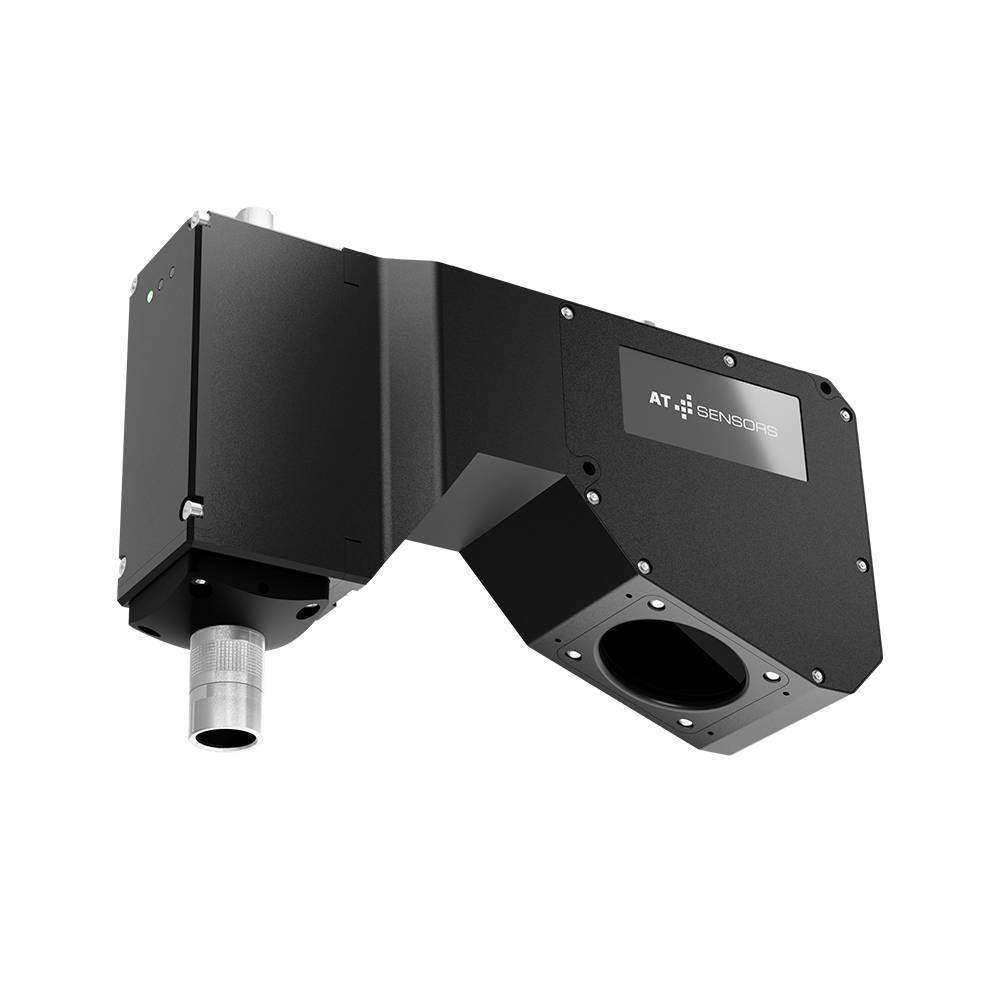

Modular 3D Compact Sensor (MCS Standard)

The Modular 3D Compact Sensor (MCS) from AT – Automation Technology is revolutionizing 3D image processing with its unique modularity, flexibility and high performance.

This innovative system allows individual configuration in terms of scan width, measurement accuracy, speed, triangulation angle and working distance to perfectly match the needs of specific applications.

With an unprecedented profile speed of 200 kHz and a resolution of 4096 points per profile, the MCS sets technological standards. It overcomes traditional hurdles such as high NRE costs and long development times by combining the reliability of a series product with the flexibility of a customized solution, without additional costs or minimum order quantities.

Application recommendation

- Electronics & Semicon

- eMobility & Battery

- Automotive

- Metrology

- Industrial Automation

- Transportation

- Iron & Steel

- Pharmaceuticals

- Sorting & Recycling

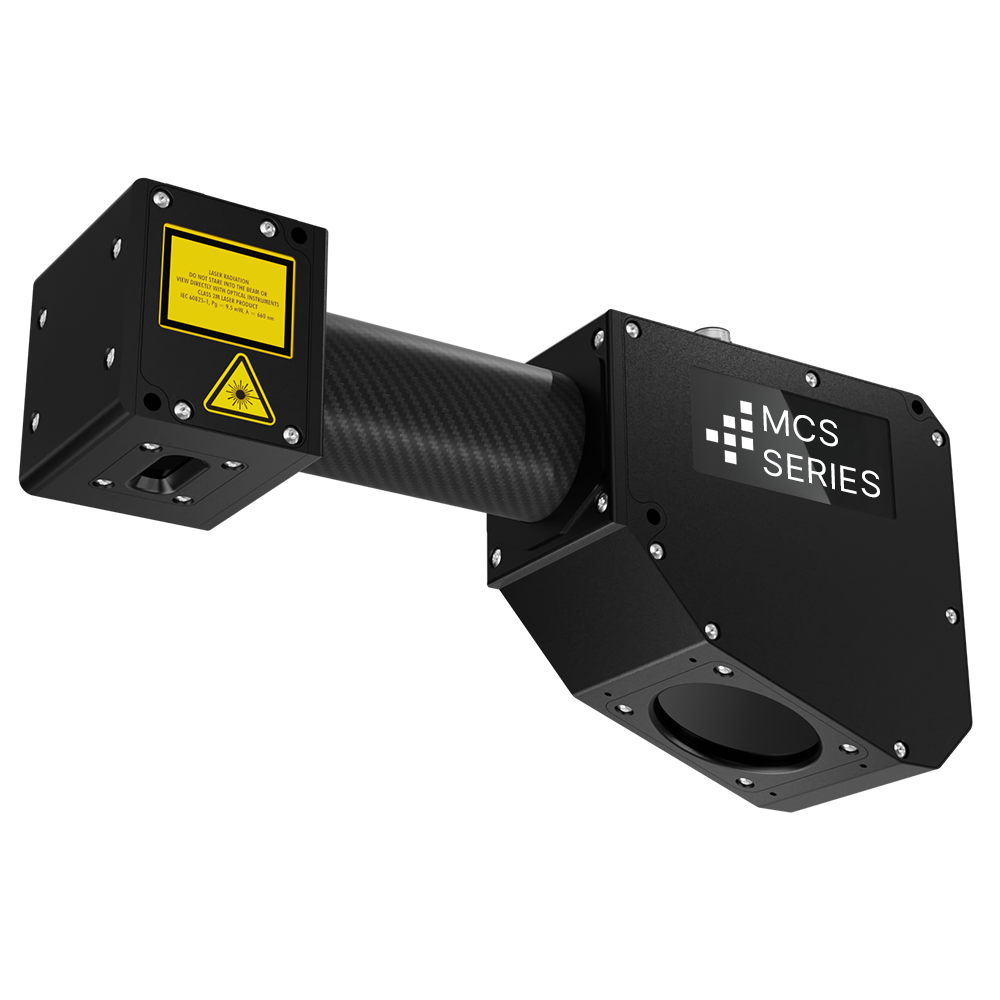

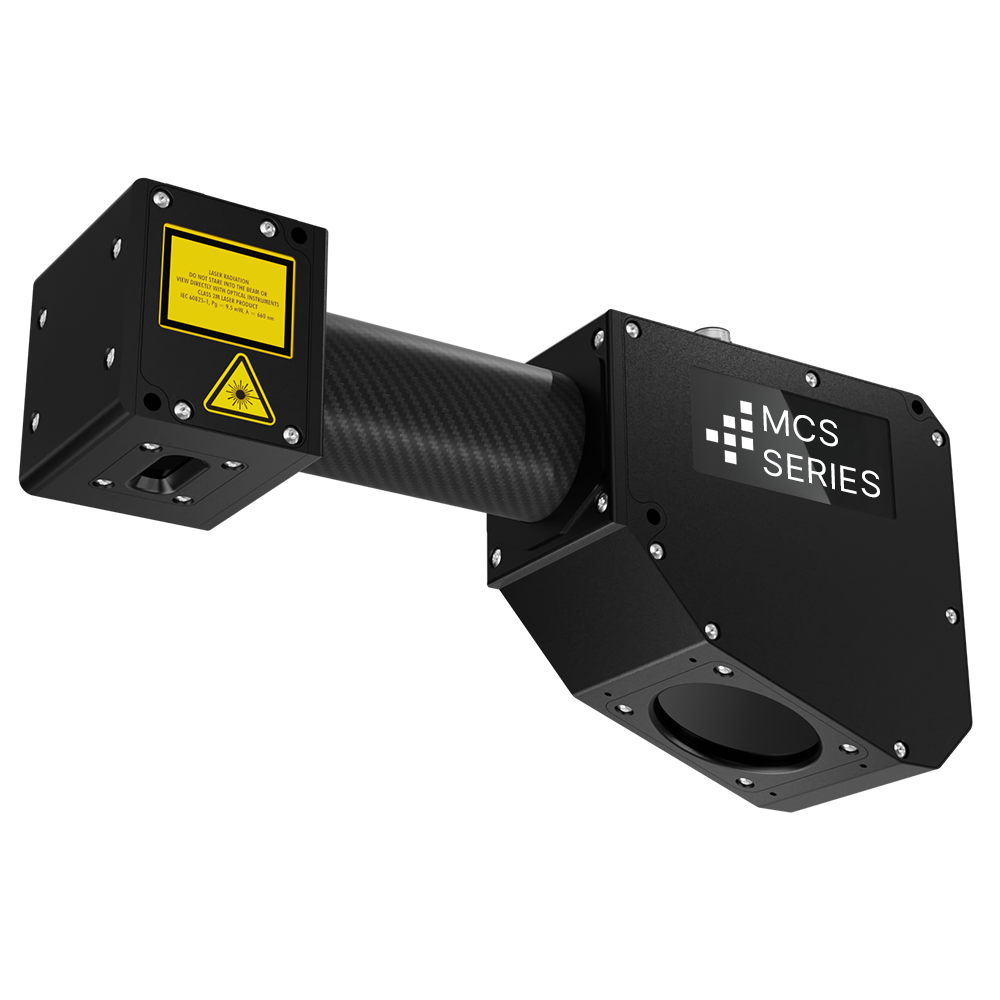

MCS High Power Laser

The new MCS High-Power Laser delivers stable, high-precision 3D scans – even in direct sunlight, on red-hot metal surfaces, or across large working distances.

With scan widths of up to 2.8 m, 17× laser power, and modular configuration, it’s the ideal solution for demanding industrial applications from road surface measurement to the steel industry.

Like all models in the MCS series, it can be flexibly configured and precisely tailored to your application.

Benefits

- Higher Laser Power (10x more output power compared to standard)

- Faster scan rates in demanding environmental conditions like difficult lighting such as bright ambient light

- for applications where high speed or a large working distance is required

Application recommendation

- Road Pavement Scanning

- Inspection of cold or red-hot steel parts

- Scanning of railroad infrastructure

| MCS Standard | MCS High Power Laser | |

|---|---|---|

| Laser Wavelength | 405, 660 nm | 450, 760, 808 nm |

| Laser Power | up to 200 mW | up to 2500 mW |

| Laser Class | 2M, 3R, 3B | 3B |

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information