Mobile NDT System From AT – Automation Technology Becomes International Industry All-Rounder

[sc_list color=”2″]

- C-CheckIR enables non-destructive testing of fiber composites on site

- Measurement within seconds on both vertical and horizontal surfaces

- Continuously new applications worldwide due to flexible adaptation to material, measurement size and measurement technology

- Cross-industry NDT use from automotive and aerospace to marine and aeronautics

[/sc_list][sc_image position=”centered” disable_lightbox=”1″ src=”/8648″]Bad Oldesloe. Innovative technology, effective testing method and uncomplicated handling: The C-CheckIR from AT – Automation Technology has redefined active thermography as a mobile system for non-destructive testing and has now become an absolute must-have product when it comes to on-site testing and maintenance of fiber composite components. After all, the mobile NDT system is no longer used only in the aviation industry for inspecting aircraft parts. Meanwhile, the C-CheckIR has established itself as a particularly powerful testing method across all industries worldwide.

Lamborghini Relies on Quality Control by C-CheckIR

Vetorix, one of AT’s Italian NDT partners, has already recognized the benefits of C-CheckIR for years and has therefore recently ordered several more systems. For years, Vetorix has been one of the leading providers of inspections using active thermography and serves global customers in the marine, aviation, racing and automotive industries. One of its clients, for example, is the luxury car manufacturer Lamborghini, to which Vetorix has sold some of AT’s mobile NDT systems. Lamborghini uses C-CheckIR for quality control of all fiber composite components on its cars, using non-destructive testing to inspect everything from door moldings to fenders to hubcaps for potential material defects.

C-CheckIR Reduces Production Downtime Costs

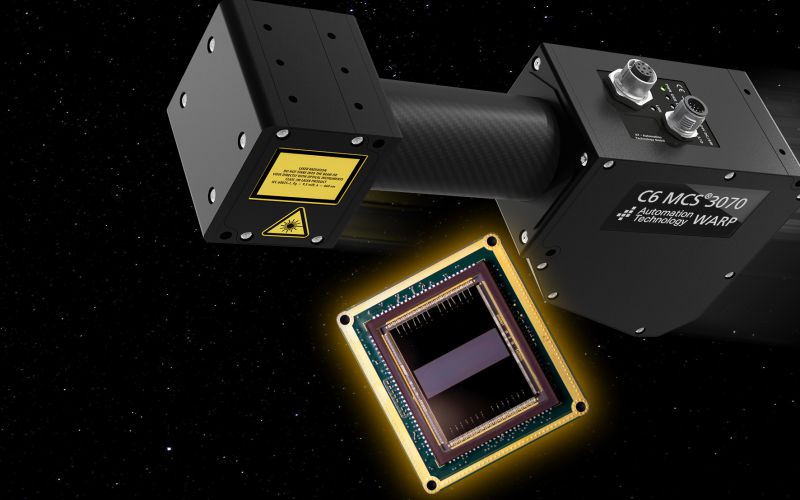

In this context, the particular advantages of the mobile NDT system from the North German technology company based in Bad Oldesloe near Hamburg, which was originally developed for an inspection of Airbus aircraft components, deserve to be highlighted. The C-CheckIR, in fact, consists of a three-legged frame equipped with vacuum suction cups at the respective ends in order to perform a measurement on both vertical and horizontal surfaces. In the center of the frame is a highly sensitive smart infrared camera and a halogen radiator with integrated power electronics as excitation source, which is controlled by the camera. The intensity of the emitter is modulated during the measurement via the so-called phase-angle control. The user in turn controls the C-CheckIR via a tablet PC, which has an intuitive user interface so that no prior technical knowledge is required to operate AT’s NDT system.

The tablet PC also makes it easy to position the sensor head at any time. A measurement takes very little time, so there is no dead time due to inspections in a production process. The inspection area is 430 x 340mm, which means that the high-performance inspection process enables large areas to be inspected quickly.

Imaging Measurement Results and Reliable Detection of Defects

For the active thermography method, the NDT system uses the halogen radiator located below the camera to thermally excite the test object. The infrared camera then analyzes the heat flow via the temperature development over the time on the component surface. The integrated thermal image processing software finally provides the user with a high-resolution result image that shows the internal structures of the component and thus also any defects such as cracks, blowholes or delaminations.

Result

With the C-CheckIR, AT – Automation Technology offers a turnkey, mobile inspection system in which the entire measurement technology is completely integrated. The product can thus be used immediately and provides the customer with a powerful and highly efficient solution for inspecting or maintaining his fiber composite components. Thanks to its flexible setting options, the measuring procedure can be optimally adapted, while the simple handling and short measuring times once again underline the capabilities of the C-CheckIR as a mobile NDT system, which virtually honors its reputation as a true all-rounder in terms of quality inspection.