The aviation industry places the highest demands on measurement technology and quality control. Components are often large scale, complex in shape and safety critical. At the same time, tight tolerances and strict requirements for traceability and reproducibility apply. Inspection processes therefore have to be precise, stable and fully integrated into production.

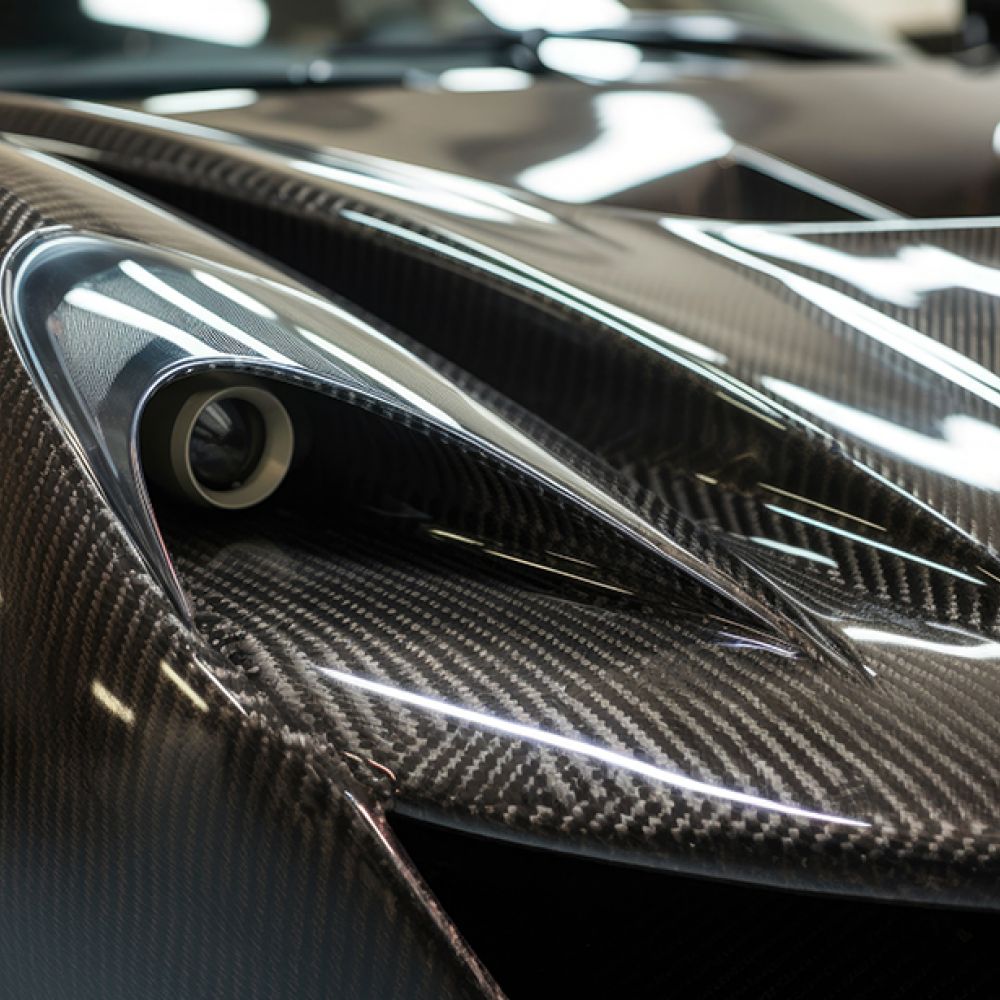

3D laser profile sensors enable contactless acquisition of height profiles, contours and geometric transitions at high resolution. Infrared cameras can additionally be used to detect material defects inside the component below the surface. Sensor solutions from AT Sensors provide reliable measurement data independent of material, surface condition or ambient light, making them ideal for demanding aviation manufacturing applications.

Typical areas of use include geometry inspection of structural components, material inspection of component parts, gap and offset measurement on fuselage and wing components, contour control of composite materials, and position verification during assembly and joining operations. Reproducible results can also be captured in real time in robot assisted or mobile measurement systems.

The result is continuous quality control with robust measurement data that safeguards processes and meets the high safety and quality standards of the aviation industry.

You are currently viewing a placeholder content from Elfsight. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information