Non-Destructive Testing in the Automotive Industry with C-CheckIR

In the automotive industry, non-destructive testing (NDT) is an integral part of quality assurance. It enables material and process defects to be detected at an early stage without damaging components or interrupting production processes.

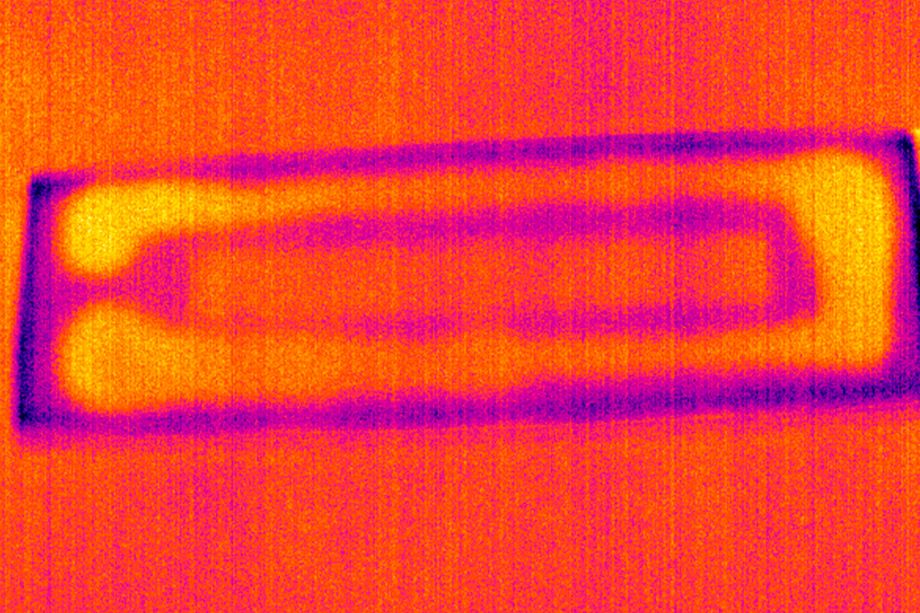

Infrared thermography has established itself as a powerful method in this field. It visualizes thermal patterns that indicate delamination, adhesive defects, frictional heat, or uneven heating. This allows defects in the manufacturing process to be identified quickly and without contact, from joining technology to CFRP/GFRP components to electronic assemblies.

With the IRSX series and its C-CheckIR, AT Sensors offers robust, inline-capable solutions for these thermographic inspection tasks. The systems are designed for industrial requirements, deliver reproducible results, and can be easily integrated into existing processes.

Challenge

Automotive production processes are highly automated, fast, and precise. To ensure seamless quality, inspection systems must be able to cope with high cycle times, changing environmental conditions, and different material properties.

The choice of the right camera depends on the required sensitivity, inspection speed, and operating conditions. Uncooled systems are quick to deploy and cost-effective, while cooled variants offer maximum sensitivity and high frame rates, but require slightly more technical effort.

Integration into automated inspection stations is also crucial. Here, IR cameras must communicate reliably with GigE Vision/GenICam, digital triggers, or PLC systems. Only in this way can temperature data be accurately linked to process steps and documented centrally.

Solution

With its C-CheckIR and IRSX series, AT Sensors provides a proven solution for thermographic NDT in the automotive industry. The systems detect the thermal radiation emitted by the component and use it to generate precise temperature fields: passively based on natural process heat or actively through targeted excitation by means of heating, flash or induction.

Typical areas of application are:

- Inspection of adhesive and welded seams based on their thermal signature

- Analysis of fiber composite components for delamination

- Monitoring of pressing and forming processes

- End-of-line inspection of safety-relevant components

- Hotspot analysis on electronic vehicle modules (e.g., ECUs, inverters)

The systems offer high frame rates, stable calibration, and comprehensive software support for parameterization, visualization, and data documentation. This allows test strategies to be automated, results to be tracked, and quality data to be evaluated efficiently.

With its C-CheckIR and IRSX series, AT Sensors delivers thermographic testing systems that are precisely tailored to the requirements of the automotive industry: fast, non-contact, reproducible, and easy to integrate into modern production and quality assurance processes.